Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Car Battery Fabrication Line?

A Car Battery Fabrication Line refers to the integrated set of manufacturing processes and equipment used to produce battery cells for electric vehicles (EVs), hybrid electric vehicles (HEVs), and plugin hybrid electric vehicles (PHEVs). It encompasses all stages from raw material preparation to cell assembly, formation, and testing.

This line is typically part of a larger battery production ecosystem, which may also include module and pack assembly lines. The fabrication line focuses specifically on celllevel manufacturing, which is the most critical and complex part of the overall process due to its impact on performance, safety, cost, and scalability.

Depending on the level of automation and scale, this can range from labscale prototyping lines to semiautomated pilot lines and finally to fully automated highvolume gigafactory lines.

Key Objectives of a Car Battery Fabrication Line

1. Produce HighQuality Battery Cells at Scale

Ensure consistent electrochemical performance

Meet automotivegrade standards for reliability and longevity

2. Enable Mass Production Efficiency

Maximize throughput with minimal downtime

Reduce waste and improve yield rates

3. Support Multiple Battery Chemistries and Formats

Accommodate NMC, LFP, solidstate, sodiumion, etc.

Support pouch, prismatic, cylindrical, and novel form factors

4. Ensure Safety and Process Control

Maintain clean and dry environments during critical steps

Implement realtime monitoring and traceability

5. Optimize for Cost and Sustainability

Reduce energy consumption and raw material waste

Enable recycling and closedloop material recovery

6. Facilitate Technology Transfer and Innovation

Allow integration of new materials and designs

Enable process improvements through data analytics and AI

Stages in a Car Battery Fabrication Line

The fabrication line consists of several interconnected stages that transform raw materials into fully functional battery cells.

1. Material Preparation and Slurry Mixing

Cathode and anode powders are mixed with solvents, binders, and conductive agents

Slurries are homogenized using planetary mixers or highshear systems

Quality checks ensure uniformity and viscosity

2. Electrode Coating

The slurry is applied onto current collectors:

Aluminum foil for cathodes

Copper foil for anodes

Slotdie coating or doctorblade methods are commonly used

Thickness and coating quality are monitored with laser sensors

3. Drying and Calendering

Electrodes are dried in ovens to remove solvents (e.g., NMP)

Drying must occur in controlled humidity and temperature conditions

After drying, electrodes are compressed using calendering machines to achieve desired density and porosity

4. Slitting and Cutting

Electrodes are cut into precise widths using slitting machines

Edge quality and dimensional accuracy are crucial for stacking or winding

Dust extraction systems prevent contamination

5. Stacking or Winding

Two main approaches:

Stacking: Used mainly for pouch and prismatic cells; layers of positive and negative electrodes are stacked with separators

Winding: Used for cylindrical cells; jellyroll configuration created by winding electrodes and separator together

Automated robotic systems ensure precision and alignment

6. Cell Assembly

The electrode stack or wound jelly roll is inserted into a cell housing (pouch, metal can, or prismatic case)

Separator placement and internal connections are verified

Tabs are welded to terminals using laser welding or resistance welding

7. Electrolyte Filling and Sealing

Must be done in a dry room environment (<1% RH) to avoid moisture contamination

Electrolyte is injected precisely into the cell

Cell is sealed immediately after filling to prevent exposure to air

8. Formation and Aging

First charge/discharge cycle ("formation") activates the cell chemistry

Cells undergo aging under controlled conditions to stabilize performance

Formation data is recorded for traceability and sorting

9. Testing and Sorting

Electrical tests measure capacity, internal resistance, and voltage stability

Mechanical tests check for leaks, seal integrity, and structural strength

Cells are sorted based on performance metrics before shipping or further assembly

Types of Car Battery Fabrication Lines

Fabrication lines can vary significantly depending on the battery type, scale, and automation level:

1. LabScale Fabrication Line

Manual operations, small batches

Focus: research, material testing, proofofconcept

Equipment: gloveboxes, small coaters, manual stackers

2. Pilot Fabrication Line

Semiautomated, flexible setup

Focus: process development, validation, smallscale trials

Equipment: modular machines, MESintegrated systems

3. Mass Production Fabrication Line

Fully automated, highspeed systems

Focus: gigafactorylevel output (GWh/year)

Equipment: continuous coating lines, robotic winders, AIcontrolled systems

Supporting Infrastructure in a Car Battery Fabrication Line

To ensure safe and efficient operation, several critical support systems must be integrated:

1. Clean Room & Dry Room Systems

Ultralow humidity zones for electrolyte filling and electrode handling

HEPA filtration to remove particulates

Climate control for optimal process conditions

2. Fire Safety and Explosion Protection

Gas detection systems for solvent vapors

Inert gas blanketing in mixing and drying areas

Fire suppression systems with clean agents or water mist

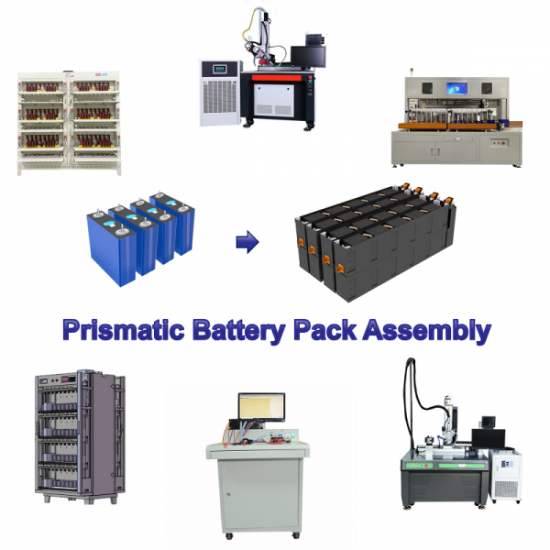

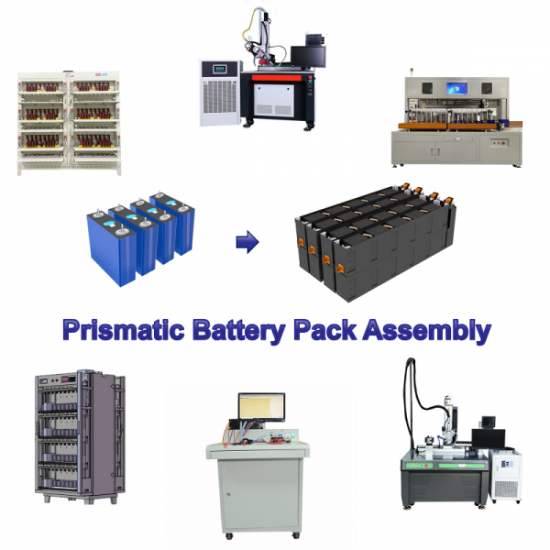

Prismatic Cell Assembly Line

3. Digital Manufacturing and Traceability

MES (Manufacturing Execution System) – Realtime process tracking

IoT sensors and PLCs – Monitor pressure, temperature, humidity

AIbased vision systems – Detect defects in coatings and welds

Traceability systems – Track each cell from raw materials to shipment

4. Sustainability and Waste Management

Solvent recovery systems – Reuse of NMP

Battery recycling integration – Closedloop material recovery

Energyefficient HVAC and lighting

Water treatment systems – For cleaning and process water

5. Automation and Robotics

Automated conveyor systems – Move materials and components

Robotic arms – Handle electrodes, stack components, load/unload machines

Laser welding and cutting – Highprecision joining and trimming

Smart testing systems – Autosort cells based on test results

Applications of a Car Battery Fabrication Line

Car battery fabrication lines are essential across various sectors:

1. Battery Manufacturers

Producing cells for OEMs and EV brands

Developing proprietary technologies and chemistries

2. Automotive OEMs

Vertical integration of battery production

Customization of battery packs for vehicle platforms

3. Startups and Innovators

Scaling up new battery technologies

Attracting investment and strategic partnerships

4. Government and Industrial Parks

Building local battery supply chains

Supporting national electrification strategies

5. Tier 1 Suppliers

Supplying modules and packs to OEMs

Integrating BMS, cooling, and safety systems

Benefits of a Car Battery Fabrication Line

Enables largescale production of EV batteries

Reduces dependency on external suppliers

Supports innovation in battery chemistry and design

Improves cost efficiency and product consistency

Strengthens local industrial ecosystems

Promotes sustainability and circular economy practices

Provides competitive advantage in the EV market

Leading Companies Involved in Car Battery Fabrication Line Development

Here are some key global players involved in designing, building, and operating car battery fabrication lines:

Battery Manufacturers:

CATL (China) – World’s largest EV battery supplier

BYD (China) – Blade battery technology

Panasonic (Japan) – Partner to Tesla for cylindrical cells

Samsung SDI (South Korea) – Highenergydensity solutions

ACC (France) – European battery cell manufacturer

Research Institutions:

Fraunhofer Institute (Germany) – Advanced battery production R&D

Argonne National Laboratory (USA) – Materials and process innovation

KRICT (South Korea) – Battery chemistry and pilotscale work

CSIRO (Australia) – Sustainable battery development

Equipment and Automation Providers:

KUKA (Germany) – Robotic automation

Siemens (Germany) – Digital twin and MES platforms

Trumpf, IPG Photonics (Global) – Laser welding and cutting

Hanson Robotics, Gree EnergyTech (China) – Integrated battery line solutions

B&R Automation (ABB subsidiary) – Smart manufacturing systems

Engineering and EPC Firms:

Bechtel, Hatch, Black & Veatch (Global) – Turnkey plant construction

Wood, Jacobs, GHD (Global) – Engineering and sustainability consulting

Need Help Designing or Optimizing Your Car Battery Fabrication Line?

If you're looking to build, expand, or optimize your car battery fabrication line, I can help you with:

Master planning – Site selection, process flow, zoning

Process engineering – Battery chemistry, format, and production stages

Factory layout design – Clean/dry room integration, workflow

Equipment sourcing – Bestinclass machinery and automation

Sustainability strategy – Green energy, recyclability, circular economy

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, permits, worker safety

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, solidstate, pouch)

Target annual production capacity (e.g., 10–100 MWh/year or more)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service