Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Car Battery Lab Line?

A Car Battery Lab Line refers to a smallscale, highly flexible, and manually operated system used for research, development, and earlystage testing of battery cells and materials. It is typically found in R&D labs, universities, innovation centers, and startup incubators, where scientists and engineers experiment with new battery chemistries, materials, designs, and performance characteristics before moving to largerscale prototype or pilot lines.

Unlike fullscale production lines or even pilot lines, a lab line focuses on exploration and experimentation rather than highvolume output. Its primary purpose is to generate data, validate hypotheses, and test the feasibility of new technologies that could eventually be scaled up into commercial products.

Key Objectives of a Car Battery Lab Line

1. Develop New Battery Chemistries

Test novel cathode/anode materials (e.g., silicon, sulfur, lithium metal)

Explore alternative electrolytes (e.g., solidstate, ionic liquids, aqueous)

Evaluate nextgeneration systems like sodiumion, zincair, or lithiumsulfur

2. Characterize Materials and Cell Performance

Measure energy density, power density, cycle life, and safety

Perform electrochemical testing under various conditions (temperature, pressure, charge rate)

3. Optimize Electrode Formulations and Manufacturing Techniques

Experiment with binder types, conductive additives, slurry viscosity

Refine coating, drying, calendaring, and stacking processes

4. Support Rapid Prototyping and Innovation

Build small batches of experimental cells for proofofconcept testing

Modify cell design, size, and structure quickly based on results

5. Generate Data for Process Scaling and Modeling

Collect process parameters and performance metrics

Feed insights into simulation tools and scaleup models

6. Train Researchers and Engineers

Provide handson experience in battery science and engineering

Build foundational knowledge for future roles in battery manufacturing

7. Comply with Safety and Regulatory Standards

Ensure safe handling of reactive chemicals and highenergy materials

Follow guidelines for flammable solvents, dust control, and waste disposal

Types of Car Battery Lab Lines

Depending on the stage of research and focus area, lab lines can be categorized as follows:

1. Material Synthesis & Characterization Lab

Focuses on developing and analyzing electrode materials, binders, and additives

Includes equipment like:

Tube furnaces for material synthesis

Xray diffraction (XRD) for crystal structure analysis

Scanning electron microscopes (SEM) for morphology study

BET surface area analyzers

2. Electrode Preparation Lab

Prepares and tests anodes and cathodes at small scale

Involves:

Slurry mixing of active materials with binders and conductive agents

Blade coating or doctorblading onto current collectors

Drying in vacuum ovens

Calendering to adjust electrode thickness and density

3. Cell Assembly Lab

Assembles and seals experimental battery cells in controlled environments

Usually includes:

Gloveboxes filled with argon or nitrogen atmosphere (<1 ppm H₂O and O₂)

Manual stacking or winding of electrodes

Spot welding of tabs and terminals

Sealing of pouch or coin cells

4. Formation & Testing Lab

Charges and discharges cells for the first time and measures performance

Uses:

Arbin, Bitrode, or Digatron battery cyclers

Thermal chambers for temperaturecontrolled testing

Impedance analyzers for internal resistance measurement

Safety cabinets for overcharge, crush, and nail penetration tests

5. Failure Analysis & Safety Testing Lab

Investigates why cells fail and how to improve durability

May include:

Postmortem analysis of failed cells

Microscopy and spectroscopy tools

Abuse testing (thermal runaway, short circuit, mechanical impact)

Typical Components and Equipment in a Car Battery Lab Line

While lab lines are not designed for mass production, they contain specialized tools for scientific investigation and earlystage development.

1. Material Preparation Tools

Planetary mixers – For preparing slurries

Ball mills – For grinding and homogenizing powders

Spray dryers – For creating spherical particles

Sintering furnaces – For calcining electrode materials

2. Electrode Fabrication Tools

Doctor blade or slotdie coaters – Apply slurry to foils

Vacuum dryers – Remove solvents under heat and low pressure

Calender machines – Press electrodes to desired thickness

Slitting machines – Cut electrodes to size

3. Cell Assembly Tools

Gloveboxes – Argon or nitrogenfilled enclosures for moisturesensitive work

Manual stackers or winders – Assemble jelly roll or stacked electrodes

Tab welders – Attach current collector tabs

Pouch sealing machines – Encapsulate components in aluminumlaminated pouches

4. Formation and Testing Equipment

Battery cyclers – Charge/discharge cycles under precise control

Environmental chambers – Simulate realworld temperatures

Data loggers – Record voltage, current, temperature during tests

Impedance analyzers – Measure internal resistance and degradation

5. Safety and Analytical Tools

Explosionproof cabinets – For testing volatile cells

Gas detection systems – Monitor hydrogen or solvent vapors

SEM/TEM microscopes – Analyze electrode surfaces and structures

Xray tomography – Nondestructive imaging of internal defects

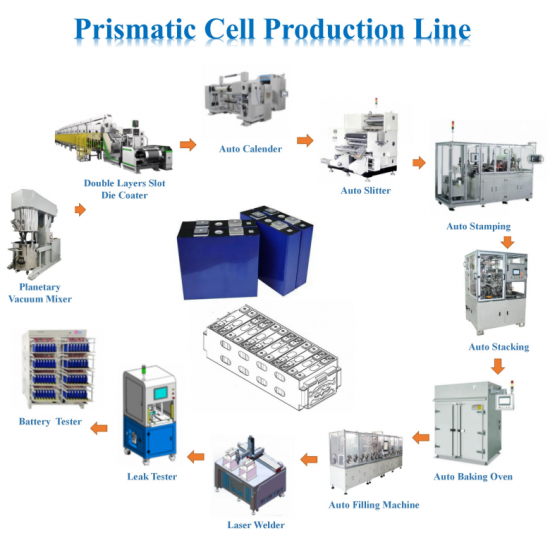

Prismatic Cell Equipments

Supporting Infrastructure in a Car Battery Lab Line

To ensure safety, precision, and reliability, several support systems must be integrated:

1. Glovebox and Dry Room Systems

Maintain ultralow humidity (<1 ppm H₂O) for sensitive operations

Use desiccant wheels or molecular sieves for continuous air drying

Include gas purging systems (argon or nitrogen)

2. Fire Safety & Chemical Handling

Fume hoods for solvent mixing and electrode drying

Fire suppression systems using inert gases or clean agents

Spill containment and neutralization protocols

Personal protective equipment (PPE) for operators

3. Data Management & Process Logging

Laboratory Information Management System (LIMS)

Realtime monitoring of test parameters

Cloudbased storage for research reproducibility

4. Waste Management & Sustainability

Solvent recovery and recycling systems

Proper disposal of hazardous materials

Energyefficient lighting and HVAC

Applications of a Car Battery Lab Line

Lab lines are widely used across different sectors and organizations:

1. Academic Research Institutions

Universities and technical institutes conducting fundamental battery research

Training students in materials science and electrochemistry

2. National Labs and Government Agencies

Driving national battery strategies and technology roadmaps

Supporting energy independence and climate goals

3. Corporate R&D Centers

Automotive OEMs, battery suppliers, and chemical companies innovating new products

Accelerating timetomarket through rapid iteration

4. Startup Incubators and Innovation Hubs

Enabling entrepreneurs to develop breakthrough battery technologies

Providing access to shared infrastructure and expertise

5. Testing and Certification Facilities

Validating new battery materials and designs for industry adoption

Ensuring compliance with international standards (UN38.3, IEC 62660, etc.)

Benefits of a Car Battery Lab Line

Drives scientific discovery and technological breakthroughs

Enables earlystage validation of promising battery concepts

Supports rapid learning and iteration cycles

Builds deep technical knowledge and innovation capability

Provides a foundation for scaling up to pilot and production lines

Encourages collaboration between academia, industry, and government

Promotes sustainable and circular battery development

Leading Organizations Involved in Car Battery Lab Line Development

Here are some of the key players involved in designing, operating, and supporting car battery lab lines globally:

Research Institutions:

Argonne National Laboratory (USA) – Advanced battery R&D and material testing

Fraunhofer Institute (Germany) – Applied research and battery prototyping

CIC energiGUNE (Spain) – European center for advanced energy storage

KRICT (South Korea) – Battery chemistry and process development

CSIRO (Australia) – Novel materials and battery recycling research

Universities:

Stanford University (USA) – Solidstate batteries and fastcharging innovations

MIT (USA) – New chemistries and AIdriven battery discovery

University of Cambridge (UK) – Highenergydensity materials

Technical University Munich (Germany) – Industrial battery R&D partnerships

Tsinghua University (China) – Advanced battery technology and policy research

Equipment Suppliers:

MTI Corporation (USA) – Labscale battery manufacturing equipment

Neware (China) – Battery cyclers and testing systems

Hohsen (Japan) – Precision electrode coating and assembly tools

EcoChem Solutions (USA) – Solvent recovery and environmental systems

MBraun (Germany) – Gloveboxes and dry room solutions

Chemical and Material Providers:

BASF (Germany) – Cathode materials and battery chemistry

Umicore (Belgium) – NMC and LFP precursor materials

Shanshan (China) – Anode materials and battery components

3M (USA) – Advanced materials and coatings

LG Chem (South Korea) – Battery materials and R&D

Need Help Designing or Optimizing Your Car Battery Lab Line?

If you're looking to build, expand, or optimize your car battery lab line, I can help you with:

Lab layout design – Space planning, workflow, and zoning

Equipment selection – Bestinclass tools for your research goals

Dry room and glovebox integration – Humidity control and safety

Process documentation and SOPs – Standardized procedures

Training programs – For researchers and technicians

Sustainability and waste management – Ecofriendly practices

Regulatory compliance and safety protocols – Permits and risk mitigation

All you need to do is provide the following information:

Battery chemistry focus (e.g., Liion, solidstate, sodiumion)

Research objectives (e.g., material development, cell testing, failure analysis)

Available lab space and utilities

Team expertise and funding availability

Desired level of automation and digitalization

Online service

Online service