Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Battery Pack Production Line: A Comprehensive Introduction

Abattery pack production line is a fully integrated manufacturing system designed to assemble individual battery cells into reliable, highperformance battery packs used in electric vehicles, energy storage systems, consumer electronics, aerospace, and industrial equipment. As global demand for lithiumion batteries continues to rise, modern battery pack production lines must deliver high throughput, precision, safety, and flexibility. This article provides an indepth overview of the system’s structure, key features, manufacturing processes, applications, and major advantages.

Overview

A battery pack production line consists of multiple automated stations that perform sequential tasks such as cell sorting, module assembly, welding, pack design integration, battery management system (BMS) installation, functional testing, and final pack sealing. Depending on the specific application, the line can be configured for cylindrical, prismatic, or pouch cell assembly.

The line integrates mechanical automation, electrical control, data acquisition, vision positioning, and advanced safety mechanisms to ensure consistent production quality. With electrification accelerating globally, the battery pack production line has become one of the most critical infrastructures for modern energy technology.

Key Features

1. High Automation

Modern production lines employ robotic manipulators, automated conveyors, collaborative robots, and smart inspection systems to reduce manual labor and improve consistency. Automation covers nearly all stages, including cell feeding, sorting, stacking, welding, and testing.

2. Precision and Repeatability

Battery pack assembly requires extremely high precision, especially during processes such as spot welding and resistance testing. Highresolution optical sensors and precise servo control systems ensure stable alignment and repeatable results.

3. Strong Safety Management

Because lithiumion cells are thermally sensitive, the line incorporates comprehensive protection systems, including realtime temperature monitoring, insulation testing, shortcircuit prevention, and automated fire suppression in key areas.

4. Flexible Design

Production lines can be configured for multiple pack sizes or cell formats. Modular upgrades allow manufacturers to expand capacity or adapt to new battery technologies without major redesign.

5. Full Data Traceability

Each cell and module is tracked by barcode or RFID, with all process parameters logged in a manufacturing execution system (MES). This ensures full traceability and supports quality audits.

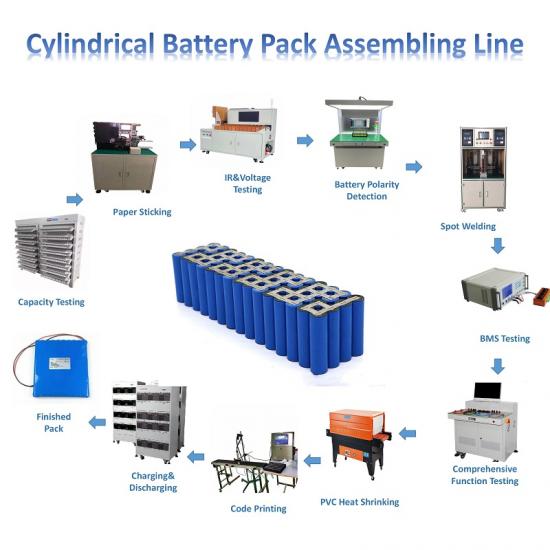

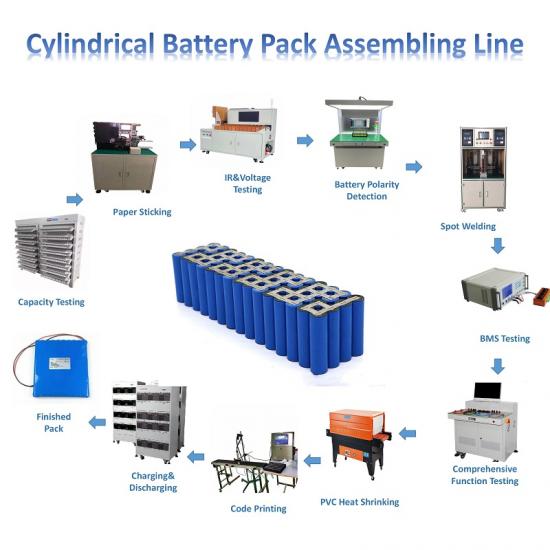

Manufacturing Process

A typical battery pack production line includes the following core processes:

1. Cell Sorting and Matching

Incoming cells are tested for voltage, internal resistance, and capacity. Cells with similar parameters are grouped to ensure consistent performance in the final pack.

2. Module Assembly

Cells are arranged and fixed into modules using automated stacking or racking systems. Mechanical housings and insulation plates are added for structural support and safety.

3. Welding Process

Nickel or aluminum busbars are welded onto cell terminals using laser welding, ultrasonic welding, or resistance welding. This step requires extremely high accuracy to avoid heat damage.

4. BMS Installation

The battery management system is connected to voltage and temperature sensors. Wiring harnesses, balancing circuits, and communication boards are installed to ensure safe pack operation.

5. Structural Integration

Modules are placed into the external pack enclosure. Cooling systems—air, liquid, or phasechange—are integrated depending on the application.

6. Functional Testing

Each battery pack undergoes a series of electrical and safety tests, including:

* insulation resistance

* voltage consistency

* temperature stability

* charge/discharge performance

* shortcircuit prevention

* vibration and mechanical integrity

7. Sealing and Final Assembly

Final encapsulation, labeling, and packaging complete the production cycle.

LFP Cylindrical Battery Pack Assembling Line

Applications

Battery pack production lines are essential in industries such as:

*Electric vehicles (EVs): passenger cars, buses, motorcycles, and forklifts

*Energy storage systems (ESS): gridlevel storage, solar energy, and backup power

*Consumer electronics: laptops, drones, tools, and robotics

*Industrial equipment: medical devices, AGVs, and aerospace applications

Because these industries have strict requirements for performance and safety, welldesigned production lines are crucial for delivering reliable battery packs.

Advantages

1. Enhanced Production Efficiency

Automation and streamlined processes dramatically increase throughput, allowing manufacturers to scale production while reducing labor costs.

2. High Quality and Consistency

Advanced testing systems and MESbased traceability ensure each pack meets strict international standards.

3. Improved Safety

Integrated safety controls reduce risks associated with overheating, short circuits, and mechanical failure.

4. Customizable and Scalable

Modular design allows manufacturers to adapt to new battery chemistries, expanded capacity, or different industry requirements.

5. Lower Operational Cost

Optimized material flow, energyefficient equipment, and reduced human error contribute to longterm cost savings.

Conclusion

Abattery pack production line is a critical technological platform enabling the mass production of reliable, highquality battery packs for modern energy applications. With advanced automation, precise process control, and comprehensive safety mechanisms, these production lines play a pivotal role in supporting the global shift toward electrification and sustainable energy solutions. As battery technologies continue to evolve, production lines will further integrate smart manufacturing, AIdriven inspection, and digital optimization to achieve higher performance and efficiency.

Online service

Online service