Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

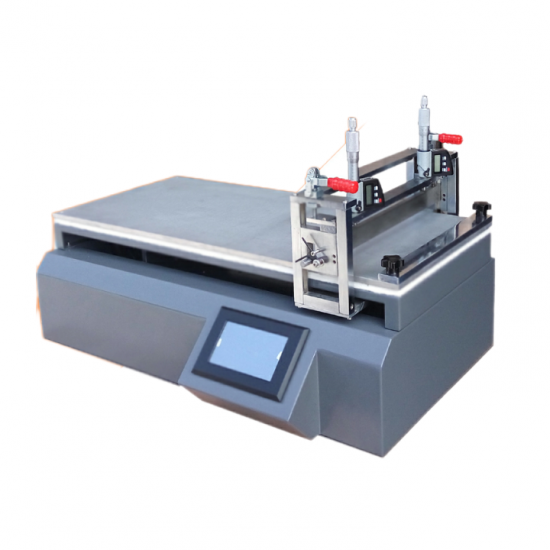

Doctor Blade Coater: Overview, Features, Process, Applications, Advantages, and Conclusion

A doctor blade coater is a precision coating machine widely used in laboratories and industrial settings to apply uniform thin films of liquids, slurries, or pastes onto substrates. This equipment is crucial for producing consistent coatings in industries such as battery manufacturing, electronics, paints and coatings, and printed electronics. By ensuring controlled thickness and smooth surfaces, doctor blade coaters enable high-quality product development and reliable performance testing.

Overview

The doctor blade coater operates on the principle of spreading a liquid material evenly across a substrate using a calibrated blade, also known as the “doctor blade.” The thickness of the applied film is determined by the gap between the blade and the substrate, allowing precise control over coating uniformity. Doctor blade coaters are suitable for a variety of substrates, including metal foils, glass, plastic, and paper, making them versatile tools for both research and production.

Key Features of Doctor Blade Coaters

Key features of modern doctor blade coaters include:

Adjustable Film Thickness: Precise control of the blade gap allows for accurate and consistent coating thickness.

High Uniformity: Ensures smooth and defect-free coatings across the substrate surface.

Versatile Substrate Compatibility: Capable of coating metal foils, flexible films, glass, and other materials.

Manual and Automated Options: Supports small-scale laboratory use and high-throughput production processes.

Precision Blade Design: High-quality blades reduce streaks, air bubbles, and other coating imperfections.

Easy Cleaning and Maintenance: Facilitates quick changeovers between different materials and formulations.

Coating Process

The typical process for using a doctor blade coater includes:

Substrate Preparation: Cleaning and drying the substrate to ensure proper adhesion.

Material Loading: Pouring or feeding the liquid, slurry, or paste onto the substrate surface.

Blade Application: A doctor blade spreads the material evenly across the substrate, controlling the film thickness through the blade gap.

Drying or Curing: The coated film is allowed to dry naturally or is cured using heat or UV light, depending on the material.

Inspection and Testing: The resulting film is analyzed for thickness, uniformity, surface defects, and performance characteristics.

Advanced automated doctor blade coaters can handle continuous coating processes and provide high reproducibility for research and industrial applications.

Heating Coater

Applications

Doctor blade coaters are widely used in:

Battery Manufacturing: Coating electrodes for lithium-ion, sodium-ion, and other advanced battery technologies.

Printed Electronics: Producing conductive, semiconductive, and dielectric films.

Coatings and Paints: Evaluating paints, inks, and functional coatings in laboratories.

Flexible Electronics: Coating films and foils for sensors, displays, and solar cells.

R&D and Pilot Production: Developing new materials and optimizing coating formulations.

Advantages

The advantages of doctor blade coaters include:

High Precision and Reproducibility: Produces consistent coatings for reliable testing and production.

Versatility: Compatible with a wide range of materials and substrate types.

Efficiency: Reduces material waste and speeds up the coating process.

Ease of Use: Simple operation for both laboratory and industrial-scale setups.

Scalability: Laboratory results can be scaled to pilot or full production lines.

Quality Control: Enables the production of defect-free, uniform films essential for advanced applications.

Conclusion

In conclusion, a doctor blade coater is an essential tool for achieving precise, uniform, and reproducible thin films across diverse applications. By combining adjustable film thickness, versatile substrate compatibility, and high uniformity, this equipment enables the development of high-performance electrodes, functional coatings, and other thin-film materials. Its applications range from battery manufacturing and printed electronics to paints, coatings, and flexible devices. With its precision, reliability, and scalability, the doctor blade coater plays a critical role in advancing material science, product quality, and industrial production efficiency.

Online service

Online service