Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Battery Assembly Line Manufacturers: Overview, Features, Process, Applications, Advantages, and Conclusion

Battery assembly line manufacturers are specialized companies that design, develop, and supply complete automated or semi-automated production lines for battery assembly. As the demand for high-performance batteries grows in electric vehicles, renewable energy storage, consumer electronics, and industrial applications, these manufacturers play a pivotal role in enabling efficient, reliable, and scalable battery production.

Overview

Battery assembly line manufacturers provide integrated solutions for producing batteries, including lithium-ion, sodium-ion, nickel-metal hydride, and other advanced chemistries. Their assembly lines typically cover the entire production workflow, from electrode preparation and cell stacking or winding to electrolyte filling, sealing, formation, and testing. By offering turnkey solutions, these manufacturers help battery producers optimize efficiency, maintain quality, and reduce production costs while meeting stringent safety and performance standards.

Key Features of Battery Assembly Line Manufacturers

Key features provided by battery assembly line manufacturers include:

Turnkey Solutions: Complete assembly lines that integrate all critical production stages.

Automation and Robotics: High-precision robots and automated systems for electrode handling, stacking, and welding.

Modular Design: Flexible configurations to accommodate different cell formats, such as pouch, cylindrical, and prismatic.

Quality Monitoring Systems: Real-time inspection of electrode alignment, electrolyte filling, sealing, and electrical testing to ensure product reliability.

Scalable Production: Lines designed for laboratory, pilot, or industrial-scale output, supporting gradual capacity expansion.

Safety and Compliance: Equipment designed to comply with industry standards for environmental, electrical, and chemical safety.

Manufacturing Process

Battery assembly line manufacturers enable the following standardized process:

Electrode Preparation: Coating, drying, calendaring, and cutting electrodes to precise dimensions.

Cell Stacking or Winding: Accurate arrangement of anode, cathode, and separator layers to form the cell core.

Electrolyte Filling: Controlled injection of electrolyte into cells to optimize ionic conductivity.

Sealing: Heat or ultrasonic sealing ensures airtight and mechanically stable cells.

Formation and Aging: Initial charge-discharge cycles stabilize the battery, by quality testing of capacity, voltage, and internal resistance.

Final Inspection and Packaging: Automated inspection for defects and proper labeling for shipment or further integration.

Advanced battery assembly lines may also include laser welding, vacuum filling, inert gas protection, and automated handling to minimize human intervention and increase efficiency.

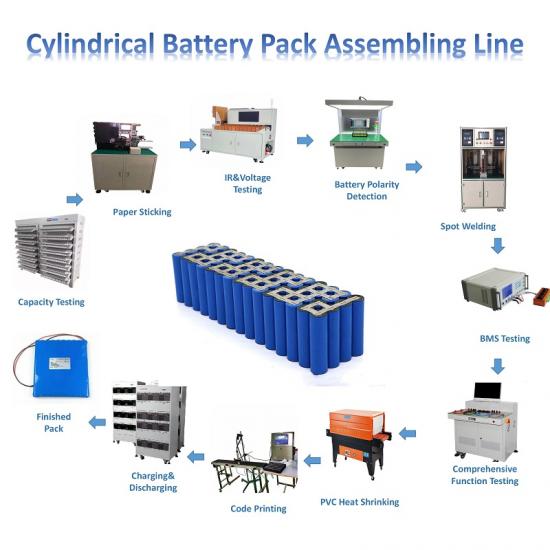

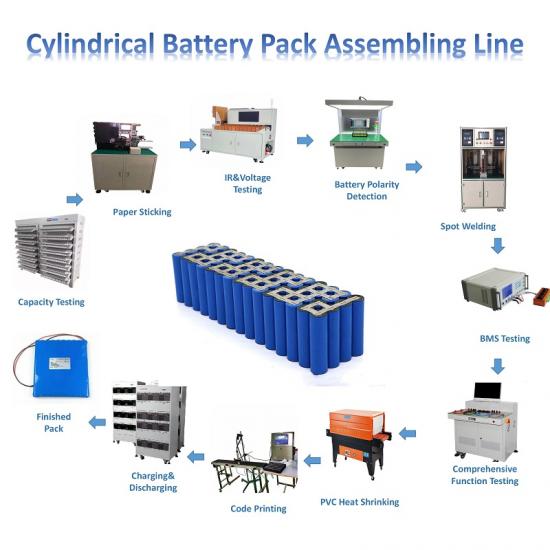

Cylindrical Battery Pack Assembling Line

Applications

Battery assembly line manufacturers serve multiple industries, including:

Electric Vehicles (EVs): Producing battery packs for cars, buses, scooters, and bikes.

Renewable Energy Storage: Manufacturing batteries for solar, wind, and hybrid energy storage systems.

Consumer Electronics: Providing compact batteries for laptops, smartphones, and portable devices.

Industrial Applications: Supplying energy storage for backup power systems, robotics, and heavy machinery.

R&D and Pilot Production: Assisting in prototyping and small-batch production for testing new materials or battery chemistries.

Advantages

The advantages of sourcing assembly lines from professional battery assembly line manufacturers include:

High Efficiency and Throughput: Automated processes reduce production time and labor costs.

Consistency and Quality: Ensures uniform cell performance and reduces defective units.

Flexibility: Supports various battery chemistries, formats, and sizes.

Scalability: Easy to expand production capacity without compromising quality.

Cost Savings: Reduces operational costs through automation, optimized workflows, and material efficiency.

Safety: Integrated safety systems protect workers, equipment, and battery materials.

Conclusion

In conclusion, battery assembly line manufacturers play a crucial role in enabling efficient, reliable, and scalable battery production. By providing turnkey solutions with automation, precision handling, quality monitoring, and safety features, these manufacturers help battery producers meet growing market demands across electric vehicles, energy storage, consumer electronics, and industrial applications. With their expertise, modular designs, and scalable solutions, battery assembly line manufacturers facilitate the production of high-performance batteries while ensuring consistent quality, operational efficiency, and compliance with industry standards, driving the advancement of next-generation energy storage technologies.

Online service

Online service