Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Battery Pack Assembly Line: A Comprehensive Technical Introduction

A battery pack assembly line is an integrated manufacturing system designed to automate, standardize, and optimize the production of battery packs used across consumer electronics, electric vehicles (EVs), energy-storage systems, and industrial equipment. As global demand for high-performance rechargeable batteries continues to rise, the battery pack assembly line has become a critical infrastructure for ensuring consistent quality, high throughput, and reliable safety standards in mass production environments. By incorporating advanced automation technologies, precision tooling, and intelligent control systems, modern assembly lines enable manufacturers to meet stringent operational and regulatory requirements.

Key Features of a Battery Pack Assembly Line

A modern battery pack assembly line is engineered with several essential features that ensure stable, repeatable, and high-quality production outcomes:

1. Modular and Scalable Structure

Battery pack assembly lines are typically built with modular workstations, allowing manufacturers to expand, reconfigure, or upgrade specific stations based on production volume or new battery designs.

2. High-Precision Automation

The line integrates robotic handling systems, automated welding modules, precision dispensing units, and optical inspection technologies. This ensures accurate positioning, consistent assembly quality, and minimized operator intervention.

3. Intelligent Monitoring and Data Traceability

Advanced manufacturing execution systems (MES) allow full tracking of cell parameters, welding quality, insulation resistance, test results, and pack serial numbers. Real-time monitoring enhances quality control and compliance with international battery safety standards.

4. Multi-Process Safety Protection

Because battery assembly involves electrical, mechanical, and thermal risks, the line is equipped with safety enclosures, fume extraction, short-circuit protection, overload monitoring, and emergency shutdown systems.

Manufacturing Process Flow

A complete battery pack assembly line consists of several interconnected production stages, each designed to ensure that individual cells are processed safely and assembled accurately into the final configuration. The standard process includes:

1. Cell Sorting and Matching

Cells are tested for voltage, internal resistance, capacity, and other parameters. Automated sorting ensures that only cells with consistent characteristics are grouped, improving pack performance and longevity.

2. Cell Stacking or Cell Arrangement

Depending on pack design, cells are arranged in series, parallel, or a combination layout. Robotic systems perform the alignment to guarantee uniform spacing and precise orientation.

3. Welding and Connection

Laser welding, ultrasonic welding, or resistance welding processes are used to connect tabs, busbars, or nickel sheets. This step requires high precision to prevent thermal damage or weak joints.

4. BMS (Battery Management System) Assembly

The battery management circuit, sensors, leads, and communication modules are installed and connected. MES systems verify wiring accuracy and BMS functionality.

5. Insulation, Enclosure, and Potting

Insulation films, protective covers, thermal pads, and structural components are added to ensure mechanical stability and electrical safety. Some pack designs include potting materials to enhance vibration resistance and fire protection.

6. Final Testing and Aging

Each battery pack undergoes comprehensive testing, including charge-discharge cycling, insulation resistance measurements, voltage calibration, and functional verification. Aging tests ensure pack stability before shipping.

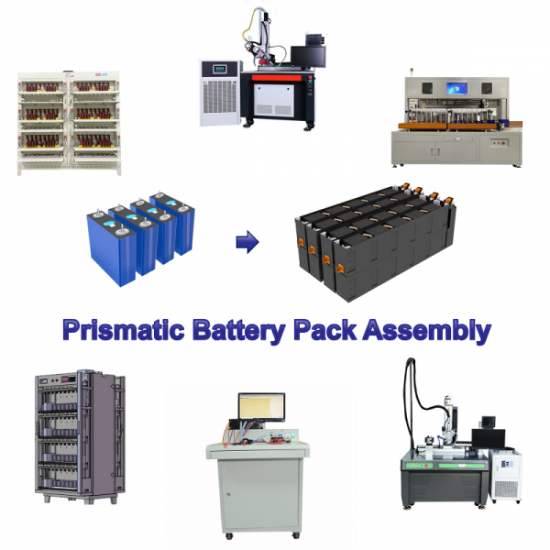

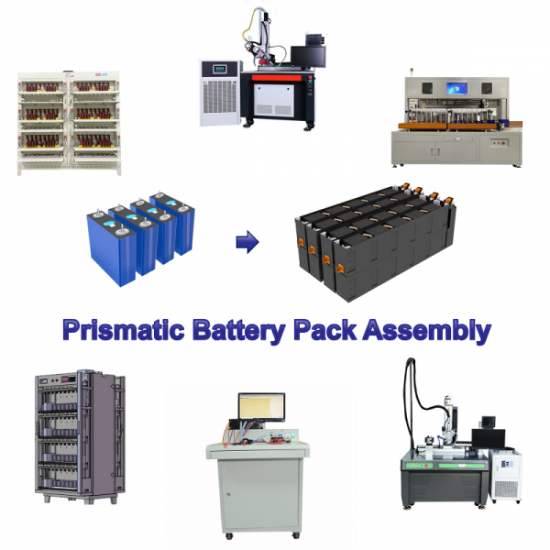

Prismatic Cell Assembly Line

Applications of Battery Pack Assembly Lines

Battery pack assembly lines serve a wide range of industries that rely on efficient and reliable energy systems. Major application sectors include:

* Electric vehicles (EVs): EV battery packs require high-capacity, high-voltage modules with strict safety and reliability standards.

* Consumer electronics: Smartphones, tablets, laptops, and portable devices benefit from compact, lightweight pack designs.

* Energy storage systems: Residential, commercial, and utility-scale storage packs require robust long-life batteries.

* Power tools and industrial equipment: High-discharge battery packs ensure consistent performance under demanding conditions.

* Medical devices: Precision manufacturing is essential to guarantee safety and reliability for medical equipment.

Advantages of a Modern Battery Pack Assembly Line

A well-designed battery pack assembly line provides numerous operational advantages:

1. Improved Production Efficiency

Automated processes significantly increase throughput while reducing labor requirements and human error.

2. Superior Quality Consistency

Precision tools, sensor-based controls, and real-time monitoring ensure uniform product quality and reduce defect rates.

3. Enhanced Safety and Compliance

Safety systems and standardized procedures ensure compliance with international regulations such as IEC, UL, and UN38.3.

4. Lower Operational Costs

Automation reduces long-term manufacturing costs by minimizing rework, material waste, and downtime.

5. Strong Flexibility and Customization

Modular design allows manufacturers to adapt quickly to new battery models, including cylindrical, pouch, and prismatic cell configurations.

Online service

Online service