Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a LiFePO₄ Prismatic Cell Production Line?

A LiFePO₄ (Lithium Iron Phosphate) Prismatic Cell Production Line is a fully integrated manufacturing system designed to produce prismaticshaped lithiumion battery cells using LiFePO₄ chemistry as the cathode material.

These production lines are used to massproduce highquality, highsafety battery cells that are widely adopted in:

Electric Vehicles (EVs) – Passenger cars, commercial vehicles, buses

Energy Storage Systems (ESS) – Gridscale storage, renewable integration, backup power

Industrial Applications – Forklifts, AGVs (autonomous guided vehicles), mining equipment

Marine and Rail Transport – Electric boats, trains, and ships

Prismatic cells are rigid, rectangularshaped batteries typically housed in aluminum or steel casings, offering structural stability, modular design, and excellent thermal safety—especially when using LiFePO₄, which is known for its inherent stability and long cycle life.

Why LiFePO₄ for Prismatic Cells?

LiFePO₄ is a preferred cathode material for prismatic cell production due to its:

High thermal and chemical stability – significantly reduces the risk of thermal runaway

Long cycle life – up to 5,000–10,000 cycles under proper conditions

Good safety performance – even under abuse conditions (overcharge, short circuit, high temperature)

Moderate energy density – suitable for applications where safety and longevity are more critical than maximum energy density

Low toxicity and environmental friendliness – contains no heavy metals like cobalt or nickel

These characteristics make LiFePO₄ prismatic cells ideal for stationary storage, commercial EVs, and safetycritical applications.

Overview of the LiFePO₄ Prismatic Cell Production Process

A typical LiFePO₄ prismatic cell production line consists of multiple interconnected stages, each optimized for high yield, quality, and efficiency. Below is a breakdown of the key process steps:

1. Electrode Manufacturing (Cathode and Anode Production)

a. Slurry Preparation

Cathode: LiFePO₄ powder is mixed with conductive carbon and a binder (e.g., PVDF) in a solvent to form a slurry.

Anode: Graphite, binder, and solvent are mixed into a slurry.

b. Coating

The slurries are coated onto current collectors:

Aluminum foil for the cathode

Copper foil for the anode

Coating is done using slotdie coating or knifeoverroll methods.

c. Drying and Calendering

Electrodes are dried in long ovens to remove solvents.

Then passed through calendering rollers to achieve the desired electrode density and thickness.

d. Slitting

Electrode sheets are slit into narrow strips to match the cell design.

2. Electrode Stacking or Winding

LiFePO₄ prismatic cells are typically manufactured using stacked electrodes rather than wound jellyroll designs, due to the rectangular shape of the cell casing.

a. Stacking

Alternating layers of cathode, separator, and anode are stacked precisely.

Can be done using Zfolding, multilayer stacking, or robotic stacking methods.

b. Tab Welding

Electrode tabs are welded to the current collectors to create electrical connections.

Often done using laser welding for precision and reliability.

3. Cell Assembly (Casing and Electrode Insertion)

a. Casing Preparation

Aluminum or steel prismatic casings are cleaned, dried, and inspected.

May include preinstallation of safety vents, current interrupt devices (CID), or pressure relief valves.

b. Electrode Stack Insertion

The stacked electrode assembly is inserted into the casing.

Insulating materials are added to prevent short circuits.

c. Electrolyte Filling

The cell is filled with LiPF₆based electrolyte under a controlled dry room environment (dew point < 40°C).

The electrolyte wets the electrodes and separator, enabling ion transport.

4. Sealing

a. Cover Plate Installation

A cover plate or lid is placed on the casing, including:

Terminal posts (positive and negative)

Safety vent (if applicable)

Sealing gasket

b. Laser Welding

The cover is laserwelded to the casing to form a hermetic seal.

Vision systems and weld inspection ensure quality.

c. Leak Testing

Postwelding leak testing using:

Helium leak detection – for highprecision microleak detection

Pressure decay testing – for faster, macrolevel leak checks

5. Formation and Aging

a. Formation

The first controlled charge/discharge cycle to activate the cell and form the SEI layer on the anode.

Done in formation cabinets under precise temperature and current control.

b. Aging (or Resting)

Cells are stored for a period (hours to days) to allow stabilization of internal chemistry.

During this time, gas evolution and electrolyte wetting are completed.

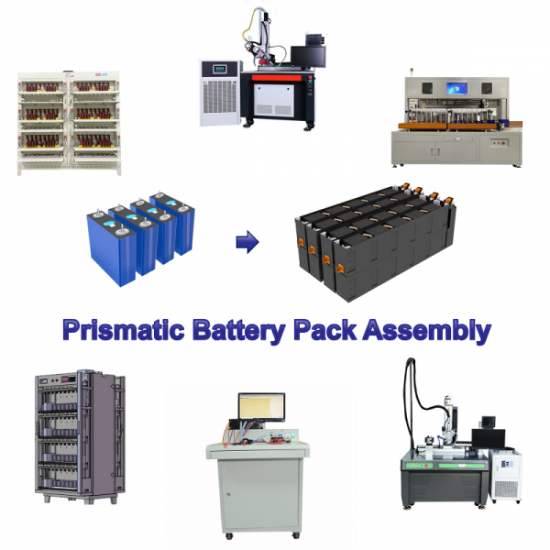

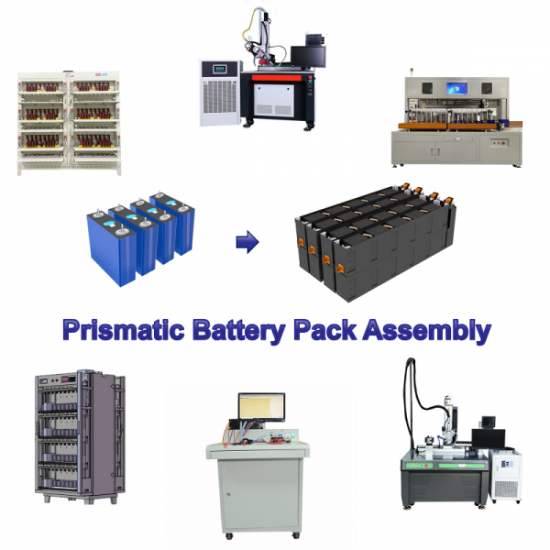

Prismatic Cell Production Line

6. Testing and Sorting

a. Initial Electrical Testing

Includes:

Voltage and internal resistance measurement

Capacity testing

Impedance analysis

b. Sorting

Cells are grouped based on performance metrics (voltage, capacity, resistance) for consistent module integration.

7. Final Inspection and Packaging

a. Visual and Dimensional Inspection

Manual or automated systems check for:

Weld quality

Surface defects

Dimensional tolerances

b. Labeling and Traceability

Each cell is labeled with:

Serial number

QR/barcode

Production date and batch number

Data is stored digitally for full traceability.

c. Packaging and Dispatch

Cells are packed in protective containers and shipped to module/pack assembly plants or directly to OEMs.

Key Equipment in a LiFePO₄ Prismatic Cell Production Line

A full production line integrates various advanced machines and systems:

| Process | Key Equipment |

|||

| Slurry Preparation | Highshear mixers, planetary mixers |

| Coating | Slotdie coaters, drying ovens |

| Calendering | Calendering machines with thickness control |

| Slitting | Slitting machines with dust removal |

| Stacking | Zfolding machines, robotic stacking systems |

| Tab Welding | Laser welders with vision alignment |

| Casing Assembly | Casing loaders, electrode insertion robots |

| Electrolyte Filling | Dry room filling stations, vacuum systems |

| Sealing | Laser welding systems, leak testing chambers |

| Formation | Formation cabinets, aging racks |

| Testing | Electrical test benches, sorting systems |

| Packaging | Labeling machines, packing systems |

Automation Levels in LiFePO₄ Prismatic Cell Production

Depending on the production scale and investment level, automation can be implemented at various levels:

1. Manual Production

Suitable for R&D, prototyping, or smallscale production

High labor involvement, limited consistency

2. SemiAutomatic Production

Combines automated core processes (coating, stacking, welding) with manual handling

Good balance between cost and productivity

3. Fully Automatic Production

Highspeed, robotdriven systems with AI vision and realtime data tracking

Found in Gigafactorylevel operations

High initial investment but offers excellent repeatability, traceability, and throughput

Design Considerations for a LiFePO₄ Prismatic Cell Production Line

When planning or setting up your production line, consider the following factors:

Cell Dimensions and Capacity – Ensure equipment supports your specific design

Production Volume – Match the layout and throughput to your daily or hourly output targets

Chemistry Specifics – LiFePO₄ has different handling and processing requirements than NMC or LCO

Dry Room Requirements – Electrolyte filling must be performed in a controlled environment (< 40°C dew point)

Safety Features – Fire suppression, explosionproof enclosures, emergency stops

Traceability and MES Integration – Digital tracking for process optimization and quality control

Factory Layout and Workflow – Optimize material flow to minimize bottlenecks

Benefits of a LiFePO₄ Prismatic Cell Production Line

High safety due to stable LiFePO₄ chemistry and robust prismatic casing

Long cycle life – ideal for energy storage and commercial vehicles

Excellent thermal stability – reduces risk of thermal runaway

Scalable production – from small R&D lines to full Gigafactory setups

Modular integration – easy to assemble into battery packs and modules

Costeffective materials – no cobalt or nickel required

Leading Companies in LiFePO₄ Prismatic Cell Production Line Equipment

Several global companies specialize in providing turnkey solutions or key components for LiFePO₄ prismatic cell production lines:

CATL (Contemporary Amperex Technology Co. Ltd.) – One of the world’s largest LiFePO₄ battery manufacturers

BYD (Build Your Dreams) – Known for Blade Battery technology using LiFePO₄ prismatic cells

KUKA Systems – Advanced robotic automation for battery production

B&R Industrial Automation (ABB) – Integrated automation platforms

Gree EnergyTech – Complete battery production line solutions

Hanson Robotics – Smart battery manufacturing systems

Hyundai WIA – Specialized equipment for automotive battery production

Trumpf, Coherent, IPG Photonics – Laser welding and sealing equipment

Need Help Designing or Setting Up a LiFePO₄ Prismatic Cell Production Line?

If you're looking to design, build, or optimize your LiFePO₄ prismatic cell production line, I can help you with:

Process flow and production planning

Factory layout and space optimization

Equipment selection and automation strategy

Supplier recommendations and cost estimation

Customization based on your specific application and production goals

All you need to do is provide the following information:

Cell dimensions and capacity

Desired production volume per day

Level of automation needed (manual/semiauto/fullauto)

Target application (EV, ESS, industrial, etc.)

Online service

Online service