Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is an EV Car Battery Production Line?

An EV (Electric Vehicle) Car Battery Production Line refers to the fully integrated system of machines, equipment, and processes used to manufacture lithiumion battery packs for electric vehicles. These production lines are designed to convert individual battery cells into modules, and then assemble those modules into a complete, vehicleready battery pack.

The battery pack is one of the most critical components of an EV, responsible for storing and delivering energy to power the vehicle. It must be assembled with high precision, safety, and reliability to ensure:

Long driving range

Fast charging capabilities

High durability over thousands of charge cycles

Compliance with automotive safety standards

EV battery production lines can be tailored to handle different cell formats, including:

Cylindrical cells (e.g., Tesla 2170 / 4680)

Pouch cells (used by LG Chem, SK On, etc.)

Prismatic cells (used by CATL, BYD, SVOLT, etc.)

Each cell type requires a slightly different production approach, but all share core principles of automation, quality control, and integration.

Key Stages in an EV Car Battery Production Line

A typical EV car battery production line consists of three major stages:

1. Cell Handling and Inspection

Before assembling the battery pack, incoming cells must be inspected, tested, and sorted to ensure consistency across the pack.

# Main Activities:

Incoming Quality Control: Check for physical damage, voltage, internal resistance, and capacity.

Sorting & Matching: Group cells with similar performance characteristics to ensure balanced behavior within the module.

Preparation: Cells may be cleaned, labeled, or preheated depending on the assembly process.

# Equipment Used:

Automated conveyor systems

Vision inspection systems

Electrical test benches

Data logging and traceability software

2. Module Assembly

Battery modules are built by arranging multiple cells together and connecting them electrically and mechanically.

# Main Activities:

Stacking and Fixturing: Cells are stacked in a predefined configuration (e.g., sidebyside or layered).

Busbar Welding: Copper or aluminum busbars are welded to connect the cells in series or parallel.

Thermal Interface Material (TIM) Application: Thermal paste or pads are applied to enhance heat transfer between cells and cooling plates.

Housing Installation: Modules are enclosed in protective frames or trays.

# Equipment Used:

Robotic stacking arms

Laser welding systems

Dispensing systems for TIM

Fixtures and clamping tools

Realtime weld inspection systems

3. Pack Integration

In this stage, multiple modules are combined into a complete battery pack, along with other critical components.

# Main Activities:

Module Insertion: Modules are placed into the battery housing or enclosure.

BMS (Battery Management System) Integration: The BMS is connected to monitor and manage each module’s performance.

Cooling System Installation: Liquid cooling plates or air ducts are installed to regulate temperature.

Wiring and Harness Connection: Highvoltage cables, sensors, and connectors are routed and secured.

Final Sealing and Leak Testing: For liquidcooled packs, pressure and leak testing ensures no coolant leakage during operation.

# Equipment Used:

Pack assembly robots

BMS installation stations

Cable routing and crimping tools

Leak testing chambers

Torquecontrolled fastening systems

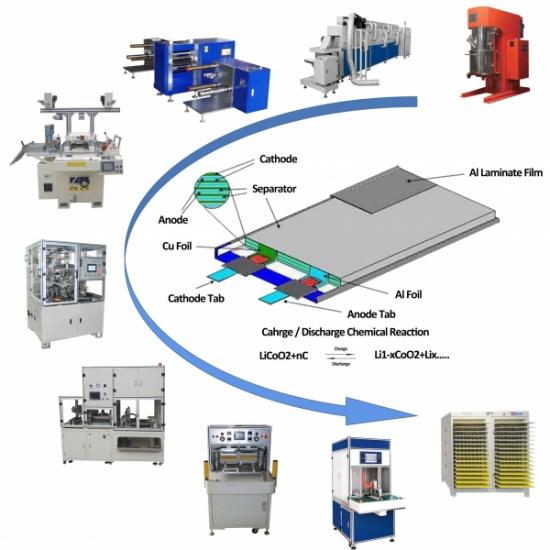

Pouch Cell Production Line

Final Testing and Validation

Once the battery pack is fully assembled, it undergoes comprehensive testing and validation to ensure performance and safety.

# Tests Conducted:

Electrical Performance Testing: Voltage balance, internal resistance, insulation resistance

Functional Testing: Communication with vehicle controller, BMS calibration

Thermal Performance Testing: Heat distribution and cooling efficiency

Safety Testing: Overcurrent, short circuit, and thermal runaway protection

Environmental Aging: Exposure to simulated realworld conditions (vibration, temperature extremes)

# Equipment Used:

Highvoltage test benches

Data acquisition systems

Vibration and environmental chambers

Functional testers with CAN communication interface

Supporting Systems in an EV Battery Production Line

To ensure highquality output and efficient operations, several supporting systems are integrated throughout the production line:

1. MES (Manufacturing Execution System)

Tracks every step of the production process

Ensures full traceability from cell to final pack

Integrates with ERP systems for inventory and scheduling

2. Clean Room and Dry Room Environments

Especially important during cell handling and electrolyte filling (if done inhouse)

Maintains low humidity (<1% RH) and particulatefree air

3. Fire Suppression and Safety Systems

Critical due to the flammable nature of lithiumion batteries

Includes gas suppression systems, fire detection sensors, and explosionproof enclosures

4. Automated Guided Vehicles (AGVs)

Transport materials and subassemblies between workstations

Reduces manual labor and improves workflow efficiency

Automation Levels in EV Battery Production Lines

Depending on the scale and investment level, automation can vary:

1. Manual Production

Suitable for R&D, prototyping, or smallscale production

Laborintensive, limited repeatability

2. SemiAutomatic Production

Combines automated key steps (welding, testing) with manual handling

Offers flexibility and costefficiency

Ideal for midvolume production or custom applications

3. Fully Automatic Production

Highspeed, robotdriven systems with AI vision and realtime data tracking

Found in largescale EV manufacturing plants (e.g., Tesla Gigafactories, CATL, BYD)

High initial investment but offers excellent repeatability, traceability, and throughput

Design Considerations for an EV Battery Production Line

When setting up or optimizing your EV battery production line, consider the following factors:

Cell Type and Size: Cylindrical, pouch, or prismatic – each has unique handling and integration needs.

Production Volume: Match layout and throughput to daily/hourly output targets.

Vehicle Platform Compatibility: Ensure the line supports current and future vehicle models.

Level of Automation Required: Manual, semiauto, or full auto?

Space and Layout Planning: Optimize material flow and minimize bottlenecks.

Integration with BMS and Cooling Systems: Seamless communication and mechanical fit.

Traceability and MES Integration: Essential for quality assurance and recalls.

Safety Features: Fire suppression, emergency stops, explosionproof design.

Benefits of a Modern EV Battery Production Line

Enables highvolume, repeatable production of safe and reliable battery packs

Supports both lowvolume customization and mass production

Reduces failure risks through automated quality checks

Improves product consistency and reduces labor costs

Facilitates realtime monitoring and datadriven optimization

Complies with global automotive safety standards such as ISO 26262, IEC 62660, UN38.3

Leading Companies Providing EV Battery Production Line Equipment

Several global companies offer turnkey solutions or key components for EV battery production lines:

KUKA Systems – Advanced robotic automation for battery assembly

B&R Industrial Automation (ABB) – Integrated automation platforms

Gree EnergyTech – Complete module and pack line solutions

Hanson Robotics – Smart battery manufacturing systems

Hyundai WIA – Specialized automotive battery equipment

Trumpf, Coherent, IPG Photonics – Laser welding and sealing equipment

CATL, BYD, Panasonic, LG Energy Solution – Inhouse developed production systems

Need Help Setting Up or Optimizing Your EV Battery Production Line?

If you're looking to design, build, or optimize your EV battery production line, I can help you with:

Process Flow Design – From cell handling to final pack testing

Factory Layout Planning – Space optimization and workflow analysis

Automation Strategy – Selecting the right level of automation for your needs

Equipment Selection – Recommending bestinclass machinery and suppliers

Cost Estimation – Budget planning based on production volume and complexity

Customization Support – Adapting the line to your specific vehicle platform

All you need to do is provide the following information:

Cell type and dimensions (cylindrical, pouch, prismatic)

Desired production volume per day/month

Level of automation required (manual/semiauto/fullauto)

Target vehicle types (passenger cars, buses, trucks, etc.)

Current factory space and infrastructure details

Online service

Online service