Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Car Battery Fabrication Plant?

A Car Battery Fabrication Plant refers to a fullscale manufacturing facility where battery cells, modules, and packs for electric vehicles (EVs) are designed, built, and assembled. This type of plant typically represents the final stage of battery development, following laboratory research and pilotscale testing. It is optimized for highvolume production, efficiency, quality control, and integration into automotive platforms.

These plants can vary widely in size—from midsized gigafactories producing hundreds of megawatthours (MWh) per year, to massive facilities capable of gigawatthour (GWh) output, serving millions of EVs annually.

The main goal of a car battery fabrication plant is to turn raw materials and validated processes into safe, reliable, highperformance battery systems ready for installation in electric cars.

Key Objectives of a Car Battery Fabrication Plant

1. Mass Production of Battery Cells

Manufacture thousands to millions of individual cells daily

Ensure consistency, reliability, and safety at scale

2. HighQuality Module and Pack Assembly

Integrate cells into modules and full battery packs

Install cooling systems, brackets, sensors, and battery management systems (BMS)

3. Process Automation and Efficiency

Use robotics and AIdriven systems to optimize throughput

Minimize waste and maximize yield rates

4. Quality Assurance and Testing

Perform 100% inspection of critical components

Conduct electrical, mechanical, and environmental tests

5. Integration with Vehicle Platforms

Customize pack designs for specific car models

Coordinate with OEMs on thermal management, packaging, and software interfaces

6. Sustainability and Recycling Readiness

Incorporate ecofriendly materials and energyefficient processes

Design for endoflife recycling and secondlife applications

7. Scalability and Flexibility

Adapt quickly to new chemistries (e.g., solidstate, sodiumion)

Support future product lines and global expansion plans

Core Stages in a Car Battery Fabrication Plant

1. Material Preparation and Slurry Mixing

Industrialscale mixing of cathode and anode materials

Precise blending of active materials, binders, solvents

Quality checks on viscosity, solids content, and particle distribution

2. Electrode Coating and Drying

Continuous coating of electrode slurries onto metal foils (copper for anodes, aluminum for cathodes)

Highspeed drying ovens remove solvents under controlled conditions

Thickness and uniformity monitored using laser sensors and machine vision

3. Electrode Calendering and Slitting

Press electrodes to desired density and thickness

Cut them into precise widths for cell assembly

4. Cell Assembly

This varies depending on the cell format:

Cylindrical: Winding of electrodes and separator, insertion into steel cans

Pouch: Stacking of electrodes and separator, sealing in aluminumlaminated pouches

Prismatic: Similar to pouch but housed in rigid metal casing

All assembly must occur in dry rooms with dew point below –40°C to prevent moisture contamination.

5. Electrolyte Filling and Sealing

Inject liquid electrolyte into each cell

Hermetically seal the cell to prevent leakage

Maintain strict cleanliness standards to avoid impurities

6. Formation and Aging

First charge ("formation") activates the electrochemical system

Cells undergo initial charge/discharge cycles to stabilize performance

Data collected to classify and sort cells by capacity and resistance

7. Final Testing and Grading

Full characterization of electrical performance

Sorting based on metrics like internal resistance, cycle life, and selfdischarge

Defective or underperforming cells rejected

8. Module and Pack Integration

Cells grouped into modules with interconnects and structural supports

Modules assembled into complete battery packs

Cooling plates, BMS hardware, and connectors installed

9. EndofLine Testing

Final functional tests including:

Electrical continuity

Voltage balance across cells

Thermal behavior during simulated driving

Communication with vehicle BMS

Leak testing, insulation checks, and mechanical robustness verification

10. Packaging and Shipment

Battery packs packed in protective crates

Labeled and tracked via digital systems

Shipped directly to vehicle assembly lines or service centers

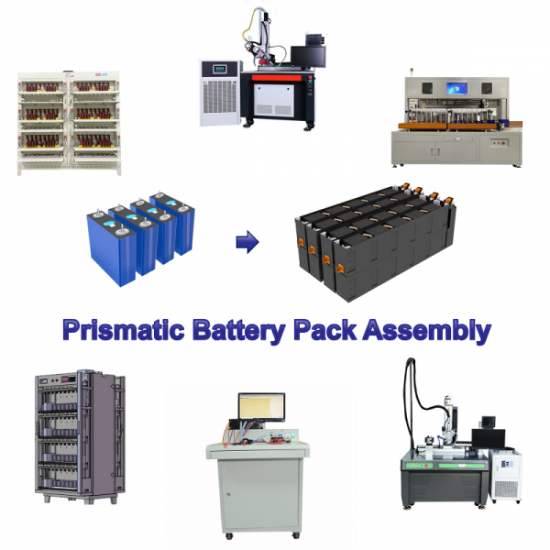

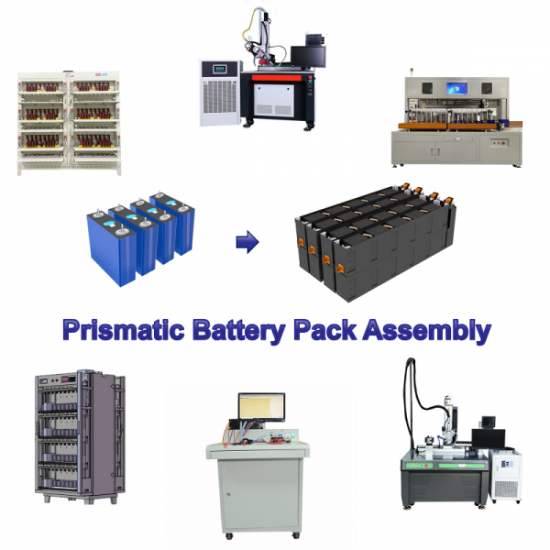

Prismatic Cell Assembly Line

Supporting Systems in a Car Battery Fabrication Plant

To ensure smooth, safe, and efficient operations, several critical support systems are integrated:

1. Clean and Dry Rooms

Maintain ultralow humidity (<1% RH) for sensitive processes

Air filtration and pressure control prevent contamination

2. Fire Suppression and Safety Systems

Specialized fire suppression in solvent handling and testing zones

Gas detection and emergency ventilation systems

3. Waste Management and Solvent Recovery

Solvent recovery units reduce environmental impact

Proper disposal of hazardous chemicals and waste materials

4. Digital Manufacturing Execution System (MES)

Realtime monitoring of all production steps

Traceability from raw materials to final shipment

Predictive maintenance and process optimization tools

5. Energy and Sustainability Infrastructure

Renewable energy sources (solar, wind)

Energyefficient HVAC, lighting, and machinery

Water recycling and closedloop cooling systems

6. Logistics and Supply Chain Integration

Justintime delivery of raw materials

Automated storage and retrieval systems (AS/RS)

Coordination with vehicle OEMs for justinsequence (JIS) delivery

Types of Car Battery Fabrication Plants

Depending on ownership, technology focus, and market strategy, fabrication plants come in various forms:

1. OEMOwned Gigafactories

Built by automakers to secure battery supply

Example: Tesla Gigafactory Nevada, Lucid Arizona, BMW South Carolina

2. Battery Manufacturer Facilities

Operated by companies like CATL, LG Energy Solution, BYD, Panasonic

Serve multiple OEMs globally

3. Joint Venture Plants

Collaborations between automakers and battery suppliers

Example: Ford + CATL, Stellantis + Samsung SDI, MercedesBenz + ACC

4. Startup and New Entrant Plants

Built by emerging battery companies entering the market

Often supported by venture capital or government grants

Example: Factorial, QuantumScape, SVOLT

5. Publicly Funded or National Battery Hubs

Governmentbacked facilities to build local battery ecosystems

Example: Northvolt Sweden, ACC France, Enovix USA

Leading Countries and Companies in Car Battery Fabrication

Top Countries Investing in Battery Fabrication:

China – Largest number of gigafactories and battery exports

United States – Rapid growth driven by Inflation Reduction Act (IRA)

Germany – Strong industrial base and EU battery strategy

South Korea – Home to toptier battery manufacturers

Sweden, France, Canada, India, UK – Growing investments in local production

Major Players:

CATL (China) – World’s largest battery supplier

BYD (China) – Produces both batteries and EVs

LG Energy Solution (South Korea) – Supplies major global OEMs

Panasonic (Japan) – Longterm partner of Tesla

Northvolt (Sweden) – Sustainable European battery leader

ACC (France) – European joint battery initiative

Tesla (USA) – Fully vertically integrated battery and vehicle production

Benefits of a Car Battery Fabrication Plant

Supports largescale adoption of electric vehicles

Reduces dependency on foreign battery supply chains

Enables localization of jobs and innovation

Drives down battery costs through economies of scale

Accelerates transition to clean mobility and energy independence

Facilitates reuse and recycling of valuable materials

Need Help Designing or Optimizing Your Car Battery Fabrication Plant?

If you're looking to build, expand, or optimize your car battery fabrication plant, I can help you with:

Factory layout and process flow design

Equipment selection and automation strategy

Dry room engineering and HVAC systems

MES implementation and data infrastructure

Sustainability planning and energy efficiency

Cost modeling and ROI analysis

Compliance, safety, and permitting guidance

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, cylindrical, pouch, prismatic)

Target annual production capacity (e.g., 1 GWh–100 GWh/year)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service