Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Car Battery Lab Plant?

A Car Battery Lab Plant (also known as a Battery R&D Lab or Battery Technology Development Lab) is a specialized facility dedicated to the research, testing, and earlystage development of battery technologies for use in electric vehicles (EVs), hybrid electric vehicles (HEVs), and energy storage systems. Unlike fullscale manufacturing plants or pilot lines, a lab plant focuses on scientific exploration, material innovation, electrochemical characterization, and smallbatch prototyping.

This type of facility plays a crucial role in the battery innovation cycle, enabling scientists and engineers to:

Explore new materials and chemistries

Understand electrochemical behavior at the cell level

Test performance under various conditions

Identify failure modes and safety risks

Develop foundational knowledge that guides future product and process design

Lab plants are typically found within universities, government research institutions, national labs, corporate R&D centers, and startup incubators.

Key Objectives of a Car Battery Lab Plant

1. Material and Chemistry Research

Investigate new cathode, anode, electrolyte, and separator materials

Evaluate their impact on energy density, life cycle, and safety

2. Electrochemical Characterization

Measure voltage profiles, internal resistance, charge/discharge curves

Study degradation mechanisms and aging behavior

3. Cell Design and Prototyping

Build smallformat cells (coin, pouch, cylindrical) for testing

Optimize electrode coatings, thicknesses, and geometries

4. Safety and Failure Analysis

Conduct abuse tests (overcharge, short circuit, nail penetration)

Analyze thermal runaway behavior and mitigation strategies

5. Performance Validation

Test under extreme temperatures, humidity, vibration

Assess longterm durability through accelerated aging

6. Data Collection and Modeling

Gather large datasets for machine learning and predictive modeling

Use simulations to guide realworld experiments

7. Technology Readiness Level (TRL) Advancement

Move promising innovations from TRL 1–3 (basic research) to TRL 4–6 (lab validation and prototype testing)

8. Support for LargerScale Development

Provide insights for pilot line and gigafactory planning

Inform decisions about scalability, cost, and manufacturability

Core Areas Within a Car Battery Lab Plant

1. Material Synthesis and Preparation Lab

Synthesize and mix electrode materials (e.g., NMC, LFP, silicon, sulfur)

Prepare slurries with varying ratios of active materials, binders, and solvents

Dry powders and prepare precursor compounds for coating

This area often includes:

Ball mills

Highshear mixers

Vacuum ovens

Gloveboxes for handling airsensitive materials

2. Electrode Coating and Drying Station

Coat slurries onto current collectors (copper foil for anodes, aluminum for cathodes)

Control coating thickness and uniformity

Dry electrodes in controlled environments to remove solvents

Key tools include:

Slotdie coaters

Doctorblade applicators

Infrared or convection drying ovens

Surface profilometers

3. Cell Assembly Area (Glovebox or Dry Room)

Assemble coin cells, pouch cells, or small cylindrical prototypes

Stack or wind electrodes with separators

Fill with electrolyte and seal under inert atmosphere

This area must be tightly controlled to prevent moisture contamination:

Dew point below –40°C

Argon or nitrogenfilled gloveboxes

Manual or semiautomated assembly tools

4. Formation and Cycling Lab

Perform initial charging (formation) to activate the cell

Run controlled charge/discharge cycles to evaluate performance

Monitor capacity retention, internal resistance, and efficiency

Common equipment:

Battery cyclers (Biologic, Arbin, Digatron)

Thermal chambers

Data acquisition systems

5. Testing and Characterization Lab

This is where deep analysis takes place:

Electrochemical Testing: EIS (Electrochemical Impedance Spectroscopy), CV (Cyclic Voltammetry), galvanostatic cycling

Physical Testing: SEM (Scanning Electron Microscopy), XRD (Xray Diffraction), FTIR (Fourier Transform Infrared Spectroscopy)

Mechanical Testing: Crush, indentation, tensile strength

Thermal Testing: Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA)

These tools help understand how materials behave at the atomic and microstructural levels.

6. Abuse and Safety Testing Zone

Simulate realworld failure scenarios

Overcharge, external short circuits, forced discharge

Nail penetration, crush, drop, fire exposure

This helps identify risks and develop safer battery designs.

7. Data Analytics and Simulation Center

Process large volumes of test data

Use AI/ML models to predict battery behavior

Run simulations of electrochemical processes and degradation pathways

This area supports faster iteration and more informed decisionmaking.

8. Support Infrastructure

To maintain safe and accurate operations, several support systems are essential:

Dry rooms/gloveboxes – for moisturesensitive work

Fire suppression systems – especially around abuse testing

Chemical storage and ventilation – for solvent and electrolyte handling

Waste treatment – for disposal of hazardous materials

HVAC and power conditioning – to ensure stable lab environment

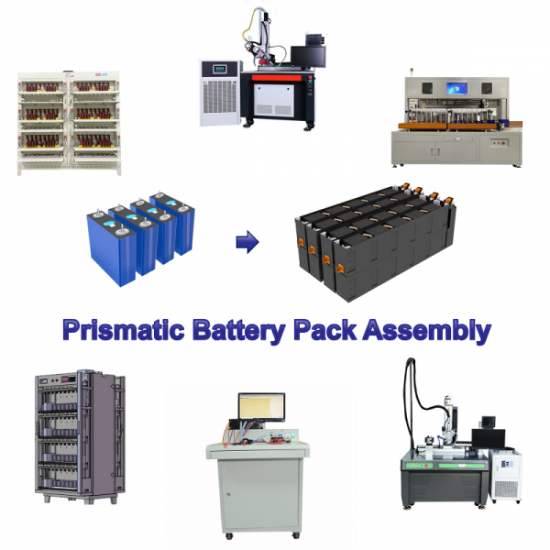

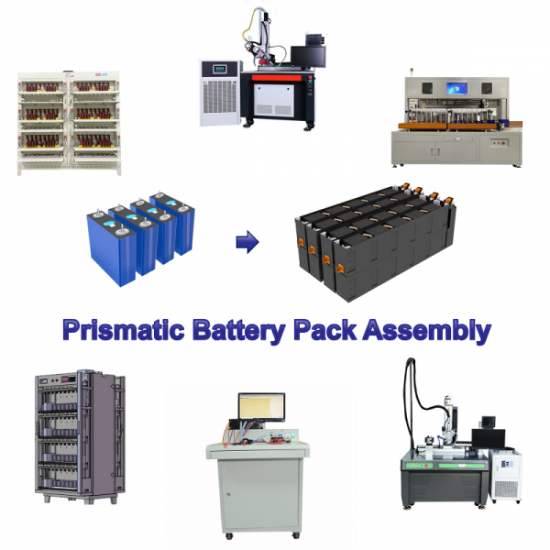

Prismatic Cell Assembly Line

Types of Car Battery Lab Plants

Depending on ownership, focus, and funding, car battery lab plants can vary significantly:

1. Academic Research Labs

Located in universities and focused on fundamental science

Often publish findings in peerreviewed journals

Example: MIT, Stanford, Tsinghua University

2. National Laboratory Facilities

Operated by government agencies like DOE (USA), Fraunhofer (Germany), CEA (France)

Focus on strategic energy and mobility goals

Collaborate with industry and startups

3. Corporate R&D Centers

Owned by automakers, battery manufacturers, or material suppliers

Aimed at developing proprietary technologies

Example: Tesla, CATL, LG Energy Solution, BASF

4. Startup Incubator Labs

Shared facilities for earlystage companies

Offer access to expensive equipment and expertise

Help validate ideas before building a pilot line

5. PublicPrivate Partnership Labs

Joint ventures between government, academia, and industry

Designed to accelerate technology transfer and commercialization

Example: Farasis + IDA Ireland, ACC France, Northvolt Labs

Supporting Technologies in a Car Battery Lab Plant

Modern lab plants rely on advanced tools and systems to enable highquality research and fast iteration:

1. HighPrecision Instruments

Electrochemical analyzers

Surface and structural imaging tools (SEM, TEM, AFM)

Thermal and mechanical testers

2. Automated Test Equipment

Multichannel battery cyclers

Environmental simulation chambers

Realtime monitoring and logging software

3. AI and Machine Learning Tools

Predictive models for battery life and failure

Optimization of material combinations and formulations

Digital twins for virtual testing

4. Cleanroom and Controlled Environments

Dry rooms with dew point control

Inert gas gloveboxes

Air filtration and pressure control

5. Sustainability Practices

Solvent recovery systems

Green chemistry approaches

Lowenergy testing protocols

6. Collaboration Platforms

Cloudbased data sharing

Remote access to instruments

Virtual meetings and training tools

Applications of a Car Battery Lab Plant

These labs serve a wide range of industries and stakeholders:

1. Battery Material Suppliers

Develop and qualify new anode/cathode materials

Optimize electrolytes and additives

2. Automotive OEMs

Evaluate nextgeneration battery tech for future EVs

Reduce dependency on thirdparty IP

3. Battery Startups

Prove novel concepts (solidstate, sodiumion, lithiummetal)

Demonstrate technical feasibility to investors

4. Government Agencies

Support national battery innovation strategies

Fund research aligned with climate and industrial goals

5. Universities and Research Institutes

Train students and researchers

Publish cuttingedge discoveries

Transfer knowledge to industry

Benefits of a Car Battery Lab Plant

Enables breakthroughs in battery performance and safety

Reduces time and risk in bringing new technologies to market

Supports sustainable and ethical battery development

Strengthens intellectual property portfolios

Fosters collaboration across disciplines and sectors

Builds local expertise and innovation ecosystems

Leading Countries and Organizations in Car Battery Lab Plants

Top Countries Investing in Battery Research:

United States – via DOE, ARPAE, and leading universities

China – strong presence in academic and corporate R&D

Germany – home to Fraunhofer, RWTH Aachen, and EUfunded projects

South Korea – wellestablished links between industry and research

Japan – pioneer in lithiumion and solidstate battery research

Sweden, France, Canada, India, UK – growing investments in battery innovation

Notable Organizations:

Argonne National Laboratory (USA) – World leader in battery R&D

Fraunhofer Institute (Germany) – Industrial battery research and testing

Northvolt Labs (Sweden) – Sustainable battery innovation

ACC (France) – European battery research and production hub

Tesla and Lucid Motors (USA) – Inhouse battery R&D for EVs

CATL & BYD (China) – Largescale battery research and development

Need Help Designing or Optimizing Your Car Battery Lab Plant?

If you're looking to build, expand, or optimize your car battery lab plant, I can help you with:

Lab layout design – Workflow, clean/dry room integration

Equipment selection – Bestinclass tools for synthesis, assembly, and testing

Process flow optimization – From material mixing to final analysis

Compliance and safety systems – Fire protection, permits, chemical handling

Digital infrastructure – Data collection, cloud storage, remote access

Training and documentation – SOPs, safety manuals, user guides

All you need to do is provide the following information:

Battery chemistry focus (e.g., NMC, LFP, solidstate, sodiumion)

Cell formats to be tested (e.g., coin, pouch, cylindrical)

Lab location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service