Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Car Battery Pilot Plant?

A Car Battery Pilot Plant is a smallscale, flexible manufacturing facility used to develop, test, and validate new battery technologies, chemistries, formats, and production processes before they are scaled up for mass production. Unlike fullscale gigafactories, pilot plants focus on research, innovation, and process optimization, serving as a critical bridge between laboratory research and industrial deployment.

These facilities allow companies, startups, and research institutions to:

Test new battery materials (e.g., cathodes, anodes, electrolytes)

Validate novel cell designs (e.g., cylindrical, pouch, prismatic, solidstate)

Optimize manufacturing workflows

Evaluate automation strategies

Ensure safety, performance, and costeffectiveness

Pilot plants are often integrated with R&D labs, testing centers, and prototyping workshops, enabling rapid iteration and datadriven decisionmaking.

Key Objectives of a Car Battery Pilot Plant

1. Technology Validation

Prove the feasibility of new battery chemistries and designs

Assess performance under realworld conditions

2. Process Development

Develop scalable and repeatable manufacturing methods

Identify bottlenecks and optimize yield rates

3. Cost Estimation

Understand material and labor costs at scale

Model capital expenditure (CapEx) and operating expense (OpEx)

4. Quality and Safety Testing

Conduct electrical, mechanical, and environmental testing

Ensure compliance with international standards (e.g., UN 38.3, IEC 62660)

5. Supporting ScaleUp Decisions

Provide data to justify investment in fullscale production

Help select optimal equipment, layout, and automation level

6. Training and Workforce Development

Train engineers and technicians on new systems

Build internal expertise before rampup

7. Partnership and Collaboration Hub

Enable collaboration between OEMs, suppliers, universities, and governments

Facilitate technology transfer and joint development agreements

Core Areas Within a Car Battery Pilot Plant

1. Material Preparation and Slurry Mixing Lab

Smallbatch mixing of electrode materials (anode/cathode slurries)

Testing different binders, solvents, and coating thicknesses

Emphasis on consistency and repeatability for earlystage validation

2. Electrode Coating and Drying Station

Precision coating of electrodes on metal foils (copper/aluminum)

Drying ovens to remove solvents

Thickness and uniformity checks using sensors and imaging tools

3. Cell Assembly Area

Stacking or winding of electrodes and separators

Insertion into casing (pouch, prismatic, or cylindrical)

Electrolyte filling and sealing under controlled environments

This area may include both manual and semiautomated workstations to simulate future production lines.

4. Formation and Aging Zone

Initial charging (formation) of cells to activate chemistry

Monitoring electrochemical behavior during early cycles

Data collection for performance prediction and grading

5. Testing and Characterization Lab

Comprehensive testing is central to a pilot plant’s mission:

Electrical: capacity, internal resistance, cycle life

Mechanical: crush, vibration, impact

Environmental: temperature extremes, humidity, altitude

Safety: overcharge, short circuit, nail penetration, thermal runaway

Test results guide design improvements and help identify failure modes.

6. Module and Pack Integration Prototyping Area

Assembling pilot cells into small modules and prototype packs

Integrating cooling plates, brackets, and BMS prototypes

Validating packlevel performance and thermal management strategies

This helps understand how individual cells behave in realworld configurations.

7. Data Analytics and Digital Twin Systems

Realtime monitoring of all processes and test results

Use of AI and machine learning to predict outcomes

Creation of digital twins for simulationbased process improvement

Digital tools accelerate learning and reduce trialanderror cycles.

8. Support Infrastructure

To ensure safe and efficient operation, several support systems are essential:

Clean/dry room HVAC – to protect sensitive processes from moisture

Fire suppression and gas detection – especially in solvent handling areas

Waste treatment and solvent recovery – for environmental compliance

Flexible layout design – allows reconfiguration for new processes

Types of Car Battery Pilot Plants

Depending on ownership, purpose, and funding, car battery pilot plants can vary significantly:

1. Corporate R&D Pilot Lines

Operated by automotive OEMs or battery manufacturers

Focused on proprietary technologies and vertical integration

Example: Tesla, CATL, BYD, Panasonic

2. Academic and Government Research Centers

Located within universities or national labs

Aimed at advancing fundamental battery science

Often supported by public funding

Example: Argonne National Lab (USA), Fraunhofer Institutes (Germany)

3. Startup Innovation Labs

Run by emerging battery tech companies

Used to prove concepts and attract investors

Often colocated with incubators or accelerators

4. PublicPrivate Partnership Facilities

Joint ventures between government, industry, and academia

Designed to build regional innovation ecosystems

Example: Farasis Energy + IDA Ireland, ACC France

5. Contract Manufacturing Pilot Plants

Thirdparty facilities offering pilot production services

Serve companies that lack inhouse capabilities

Offer flexibility and shared infrastructure

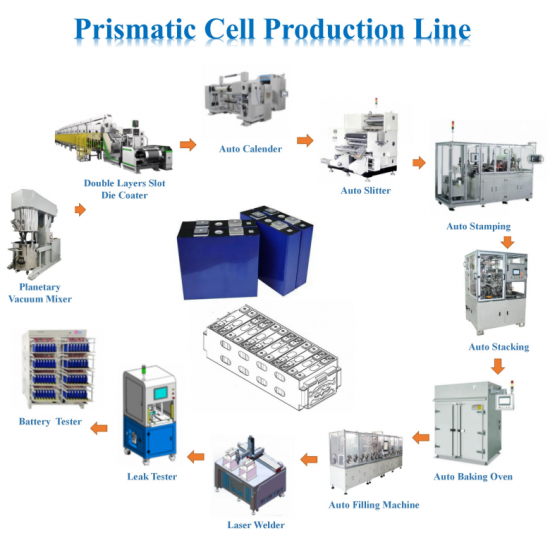

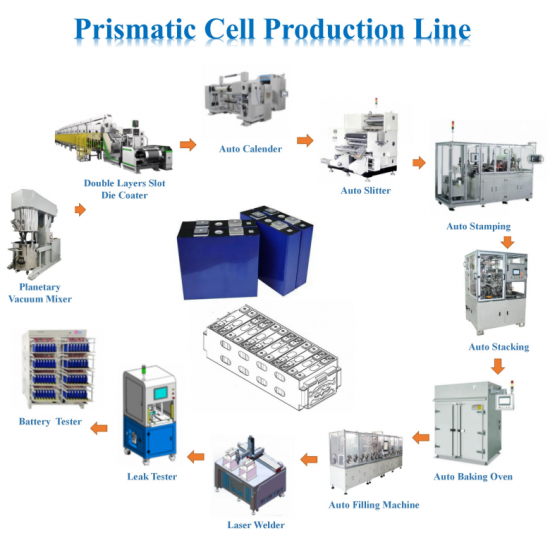

Prismatic Cell Equipments

Supporting Technologies in a Car Battery Pilot Plant

Modern pilot plants rely on advanced tools and systems to enable fast iteration and highquality output:

1. Flexible Automation Platforms

Modular machines that can be reconfigured for different chemistries or formats

Semiautomated workstations for quick prototyping

2. HighPrecision Sensors and Vision Systems

Realtime feedback on coating quality, alignment, and weld integrity

AIpowered defect detection and classification

3. Battery Simulation and Modeling Tools

Predictive modeling of battery behavior before physical testing

Helps guide formulation and design choices

4. MES and Process Monitoring Systems

Track every step of the manufacturing process

Maintain traceability from raw materials to final test data

5. Sustainability Features

Solvent recovery and reuse systems

Lowenergy drying and curing methods

Recyclable components and packaging

6. Collaboration and Remote Access Tools

Cloudbased platforms for remote monitoring and data sharing

Virtual reality (VR) tools for training and design review

Applications of a Car Battery Pilot Plant

These plants serve a wide range of industries and stakeholders:

1. Automotive OEMs

Test new battery technologies before committing to large investments

Develop custom battery solutions for upcoming EV models

2. Battery Startups

Validate novel chemistries (e.g., solidstate, sodiumion, silicon anodes)

Demonstrate manufacturability to investors and partners

3. Suppliers and Material Companies

Qualify new materials under realworld production conditions

Optimize formulations for performance and processability

4. Government Agencies

Support national battery innovation strategies

Encourage local job creation and technology leadership

5. Universities and Research Institutions

Translate labscale discoveries into practical applications

Train the next generation of battery scientists and engineers

Benefits of a Car Battery Pilot Plant

Accelerates innovation and timetomarket

Reduces risk in scaling new technologies

Improves understanding of manufacturability and cost

Enables customization for specific vehicle platforms

Strengthens intellectual property position through iterative learning

Fosters collaboration between industry, academia, and government

Supports sustainable battery development and recycling efforts

Leading Countries and Organizations in Car Battery Pilot Plants

Top Countries Investing in Pilot Line Capacity:

United States – via DOE programs, ARPAE, and state initiatives

China – extensive network of corporate and academic R&D centers

Germany – strong presence in Fraunhofer institutes and EUfunded projects

South Korea – wellestablished links between industry and research

Japan – long history in battery R&D and pilot line development

France, Sweden, Canada, India, UK – growing investments in pilotscale innovation

Notable Organizations:

Argonne National Laboratory (USA) – Advanced battery R&D

Fraunhofer Institute (Germany) – Industrialscale pilot testing

Northvolt Labs (Sweden) – Sustainable battery innovation

ACC (France) – European battery pilot and production hub

Tesla and Lucid Motors (USA) – Inhouse pilot and prototype development

CATL & BYD (China) – Largescale R&D and pilot operations

Need Help Designing or Optimizing Your Car Battery Pilot Plant?

If you're looking to build, expand, or optimize your car battery pilot plant, I can help you with:

Master planning – Site selection, zoning, logistics

Process engineering – Chemistry, format, automation level

Factory layout design – Workflow, clean/dry room integration

Equipment sourcing – Bestinclass machinery and automation

Sustainability strategy – Renewable energy, recyclability

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, permits, worker safety

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, solidstate, cylindrical, pouch)

Target annual output (e.g., 1–50 MWh/year)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service