Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is an EV Car Battery Manufacturing Plant?

An EV (Electric Vehicle) Car Battery Manufacturing Plant is a dedicated industrial facility designed to produce lithiumion battery cells, modules, and packs for use in electric vehicles. It encompasses the entire production lifecycle, from raw material processing to final battery system integration and testing.

This type of plant integrates:

Battery cell fabrication lines

Module and pack assembly systems

Quality assurance and testing labs

Material handling and logistics infrastructure

Digital manufacturing systems (MES, IoT, AI)

Supporting utilities and environmental control systems

These plants are often referred to as Gigafactories when they reach gigawatthour (GWh) scale output — capable of supplying batteries for hundreds of thousands of EVs annually.

Such facilities are essential for:

Automotive OEMs seeking vertical integration (e.g., Tesla, BMW, Ford)

Battery manufacturers aiming to expand global capacity (e.g., CATL, LG Energy Solution, Panasonic)

New market entrants building localized supply chains

Governments supporting national energy and mobility goals

Key Objectives of an EV Battery Manufacturing Plant

1. Mass Production of HighPerformance Battery Systems

Deliver reliable, highquality battery cells, modules, and packs at scale

Meet automotivegrade standards for safety, performance, and longevity

2. Localization of Supply Chain

Reduce reliance on imported components and materials

Support domestic EV manufacturing and job creation

3. Integration of Advanced Technologies

Adopt nextgen chemistries (e.g., solidstate, sodiumion)

Implement dry electrode technology, AIbased quality control, and smart automation

4. Cost Optimization Through Scale and Efficiency

Lower battery cost per kWh via process optimization and automation

Enable more affordable EVs and faster adoption

5. Sustainability and Circular Economy

Integrate recycling systems for endoflife batteries

Use renewable energy and ecofriendly production practices

Core Stages in an EV Battery Manufacturing Plant

A modern EV battery manufacturing plant typically includes the following integrated production stages:

1. Battery Cell Production Line

This is where individual lithiumion cells are manufactured. The line includes:

Slurry Mixing: Combining active materials (NMC, LFP), binders, and solvents

Electrode Coating: Applying slurry onto copper (anode) and aluminum (cathode) foils

Drying & Calendering: Removing solvent and compressing electrodes to desired density

Slitting: Cutting coated foils into precise widths

Stacking or Winding: Assembling cathodes, separators, and anodes into stacks or jellyrolls

Cell Assembly: Inserting electrodes into cases, welding tabs, and sealing cells

Electrolyte Filling: Injecting electrolyte under ultradry conditions (<1% RH)

Formation & Aging: First charge/discharge cycle and stabilization period

Final Testing: Capacity, internal resistance, and safety checks

2. Battery Module Assembly Line

Once cells are produced, they are grouped into modules with integrated thermal management and electrical connections.

Key steps include:

Cell Sorting: Matching cells by voltage, capacity, and resistance

Module Stacking: Arranging cells in series/parallel configurations

Busbar Welding: Connecting cells with laserwelded busbars

Thermal Interface Material (TIM) Application: Ensuring even heat distribution

Module Housing: Enclosing cells in protective frames

BMS Integration: Installing sensors and connectors for monitoring

3. Battery Pack Assembly Line

Modules are then assembled into complete battery packs, ready for installation in vehicles.

Steps include:

Pack Frame Preparation: Mounting brackets, cooling plates, and structural supports

Module Installation: Placing and securing modules inside the pack enclosure

Wiring Harness Installation: Connecting modules to the BMS and vehicle interface

BMS Final Integration: Programming and validating software and communication protocols

Cooling System Integration: Installing liquid cooling loops and insulation

Sealing and Leak Testing: Ensuring water and dust resistance (IP67+)

Final Functional Testing: Full poweron test, diagnostics, and safety checks

4. Testing and Validation Lab

A dedicated lab ensures that every component and finished product meets automotivegrade standards.

Testing includes:

Electrical Performance Testing: Charge/discharge cycles, efficiency, and consistency

Mechanical Testing: Vibration, impact, and compression tests

Environmental Testing: Temperature extremes, humidity, salt spray

Safety Testing: Overcharge, short circuit, nail penetration, and thermal runaway

Lifetime and Cycle Testing: Predicting longterm performance and degradation

5. Battery Management System (BMS) Development Center

The BMS is the brain of the battery system, responsible for:

Monitoring voltage, current, and temperature of each cell

Balancing charge across cells for optimal performance

Communicating with the vehicle’s central computer

Managing thermal events and fault detection

Development includes:

Firmware design and validation

Hardware design and PCB layout

Communication protocol integration (CAN, Ethernet)

Functional safety compliance (ISO 26262, ASILD)

6. Clean Room and Dry Room Infrastructure

To ensure moisturesensitive processes like coating and electrolyte filling are safe and consistent, the plant includes:

Ultralow humidity zones (<1% RH)

Solvent recovery systems

Air filtration and fire suppression systems

Explosionproof enclosures for flammable environments

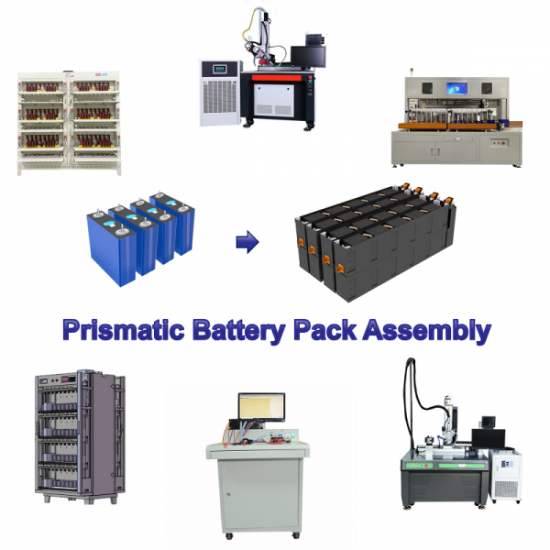

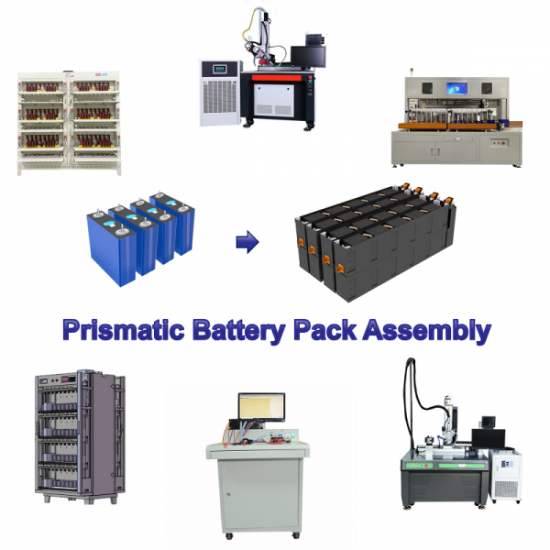

Prismatic Cell Assembly Line

7. Manufacturing Execution System (MES) and Digitalization

Modern battery plants rely heavily on smart manufacturing systems:

Realtime data acquisition and analytics

IoTenabled sensors and PLCs

MES for traceability, scheduling, and quality control

Predictive maintenance and yield optimization

Digital twins for simulation and training

8. Logistics and Material Handling

Efficient movement of materials and products is critical:

Automated guided vehicles (AGVs) and conveyor systems

Justintime inventory for raw materials and components

Climatecontrolled storage for sensitive materials

Packaging and shipping systems for finished packs

9. Energy and Sustainability Infrastructure

To support continuous operation and meet ESG goals:

Onsite renewable energy generation (solar, wind)

Battery energy storage systems (for peak shaving)

Water treatment and recycling systems

Waste management and solvent recovery units

Carbon footprint tracking and offsetting strategies

Types of EV Battery Manufacturing Plants

Depending on ownership and strategy, these plants can be categorized as:

1. OEMOwned Gigafactories

Built and operated by automotive companies

Example: Tesla Gigafactory Nevada, Ford BlueOval plants

Offers full control over integration and supply chain

2. Battery Manufacturer Gigafactories

Operated by independent suppliers

Example: CATL, LG Energy Solution, BYD

Supplies to multiple OEMs globally

3. Joint Venture (JV) Gigafactories

Collaborations between OEMs and battery makers

Example: BMW & Northvolt, Stellantis & Samsung SDI

Shares investment, expertise, and risk

4. GovernmentSupported Battery Hubs

Backed by national policies and incentives

Example: India’s PLI Scheme, EU Battery Alliance, U.S. Inflation Reduction Act (IRA)

Aims to build domestic battery ecosystems

Key Considerations When Building an EV Battery Manufacturing Plant

When planning or expanding your battery plant, consider the following factors:

| Area | Consideration |

|||

| Location | Proximity to raw materials, OEMs, skilled labor, and transportation |

| Capacity Planning | Annual output in GWh (e.g., 10 GWh, 50 GWh, 100 GWh) |

| Battery Chemistry | NMC, LFP, solidstate, etc. |

| Cell Format | Cylindrical, pouch, prismatic |

| Automation Level | Manual, semiauto, fully automatic |

| Factory Layout | Clean room placement, workflow, scalability |

| Integration Strategy | Celltopack, modulelevel integration |

| Environmental Compliance | Fire safety, emissions, waste treatment |

| Workforce Development | Training engineers, technicians, operators |

| Partnerships | Suppliers, OEMs, research institutions |

Benefits of an EV Battery Manufacturing Plant

Accelerates EV adoption through stable, largescale battery supply

Reduces battery costs via economies of scale and automation

Strengthens local industry and creates hightech jobs

Enhances energy independence and national security

Enables tech leadership in nextgeneration batteries

Supports sustainability through green manufacturing and recycling

Leading Companies in EV Battery Manufacturing Plant Development

Here are some of the key players involved in designing and operating EV battery manufacturing plants:

Battery Manufacturers:

CATL (China) – World's largest battery supplier

LG Energy Solution (South Korea) – Global expansion plans

Panasonic (Japan) – Longtime partner of Tesla

BYD (China) – Produces both batteries and EVs

Samsung SDI (South Korea) – Expanding in Europe and North America

Northvolt (Sweden) – European sustainable battery leader

Automotive OEMs:

Tesla (USA) – Multiple Gigafactories worldwide

Ford & SK On (USA & South Korea) – Joint venture plants

BMW & Northvolt (Germany) – Gigafactory in Europe

Volkswagen Group (Germany) – Investing in European Gigafactories

Stellantis (Global) – Partnering with Samsung SDI and Factorial

Equipment and Automation Providers:

KUKA (Germany) – Robotics and automation solutions

Siemens (Germany) – Digitalization and MES platforms

Trumpf, Coherent, IPG Photonics – Laser welding and cutting systems

Hanson Robotics, Gree EnergyTech – Integrated battery line solutions

B&R Automation (ABB subsidiary) – Smart manufacturing systems

Engineering and EPC Firms:

Bechtel, AECOM, Hatch, Black & Veatch – Turnkey plant construction

Wood, Jacobs, GHD – Engineering and sustainability consulting

Need Help Designing or Optimizing Your EV Battery Manufacturing Plant?

If you're looking to build, expand, or optimize your EV battery manufacturing plant, I can help you with:

Master planning – Site selection, capacity roadmap, and zoning

Process engineering – Battery chemistry, format, and production flow

Factory layout design – Space utilization, clean/dry room integration

Equipment sourcing – Bestinclass machinery and automation partners

Sustainability strategy – Green energy, recycling, circular economy

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, environmental permits, worker safety

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, cylindrical, pouch)

Target annual production capacity (in GWh)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service