Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is an EV Car Battery Assembly Plant?

An EV (Electric Vehicle) Car Battery Assembly Plant is a specialized manufacturing facility focused on integrating premade battery cells into modules and complete battery packs for installation in electric vehicles.

Unlike fullscale battery cell production plants, which manufacture the individual cells from raw materials, an assembly plant primarily deals with:

Cell sorting and grouping

Module assembly (cells → modules)

Pack integration (modules → vehicleready battery packs)

Battery Management System (BMS) integration

Testing and validation of final battery systems

These plants are often part of a larger Gigafactory complex, or can be standalone facilities located near EV assembly lines to support justintime manufacturing.

They are critical for:

Automotive OEMs integrating battery packs into vehicles

Battery suppliers delivering readytoinstall packs to OEMs

New entrants in the EV market aiming to localize battery integration

Governmentbacked EV initiatives building domestic supply chains

Key Objectives of an EV Battery Assembly Plant

1. Efficient Integration of Battery Cells into VehicleReady Packs

Assemble battery modules and packs from pretested cells

Ensure compatibility with specific EV models and platforms

2. HighQuality and Reliable Battery Systems

Maintain strict quality control during assembly

Ensure electrical, mechanical, and thermal integrity of battery systems

3. Scalable and Flexible Production

Support multiple battery pack designs for different vehicle models

Enable modular design for future upgrades and new platforms

4. CostEffective Assembly Processes

Optimize labor, automation, and logistics

Reduce cycle time and improve throughput

5. Integration of Smart Manufacturing and Traceability

Use digital systems (MES, IoT) to track every battery pack

Enable predictive maintenance and quality analytics

6. Sustainability and Reusability

Design for ease of disassembly and serviceability

Support secondlife applications and recycling strategies

Core Stages in an EV Battery Assembly Plant

An EV battery assembly plant typically includes the following integrated stages:

1. Cell Receiving and Inspection

Incoming cell inspection: Verify cell voltage, capacity, and internal resistance

Sorting and grouping: Match cells with similar performance characteristics

Storage in climatecontrolled zones: Prevent degradation before use

2. Module Assembly Line

Module stacking: Arrange matched cells in series or parallel configurations

Busbar welding: Connect cells using laser or resistance welding

Thermal interface material (TIM) application: Ensure even heat distribution

Module housing: Enclose cells in protective frames with sensors

Module testing: Verify voltage, resistance, and initial thermal performance

3. Pack Integration Line

Pack frame preparation: Install cooling plates, brackets, and structural supports

Module installation: Mount and secure modules into the pack enclosure

Electrical wiring and connectors: Install wiring harnesses and highvoltage connections

BMS installation: Mount and connect the Battery Management System

Cooling system integration: Fit liquid cooling loops and insulation

Sealing and leak testing: Ensure IP67+ protection rating

4. Final Testing and Validation

Poweron test: Check BMS communication and basic functionality

Electrical performance test: Measure voltage, current, and internal resistance

Thermal performance test: Validate cooling system efficiency

Functional safety test: Simulate faults and check BMS response

Environmental testing: Exposure to vibration, humidity, and temperature extremes

Final inspection and labeling: Assign serial numbers and prepare for shipment

5. Battery Management System (BMS) Integration and Programming

The BMS is the intelligent control unit of the battery pack, responsible for:

Monitoring individual cell voltages and temperatures

Managing charge balancing and thermal regulation

Communicating with the vehicle’s central control system

Ensuring safety through fault detection and isolation

Key activities include:

Hardware installation and connection

Firmware loading and configuration

Communication protocol setup (e.g., CAN, Ethernet)

Functional safety validation (ISO 26262 compliance)

6. Clean Room and Dry Room Infrastructure

Although less extensive than in cell production, some dry room zones are required for:

BMS installation and sensor wiring

Final pack sealing and insulation

Avoiding moisture contamination in sensitive electronics

7. Logistics and Material Handling

Efficient movement of components and finished battery packs is essential:

Automated Guided Vehicles (AGVs) and conveyors

Justintime delivery of modules and components

Packaging and shipping systems for final packs

Inventory tracking and traceability systems

8. Digital Manufacturing and MES Integration

Modern battery assembly plants use smart manufacturing systems to:

Monitor production in real time

Track every battery pack from start to finish

Collect data for quality control and yield optimization

Integrate with ERP and PLM systems

Enable predictive maintenance and process improvement

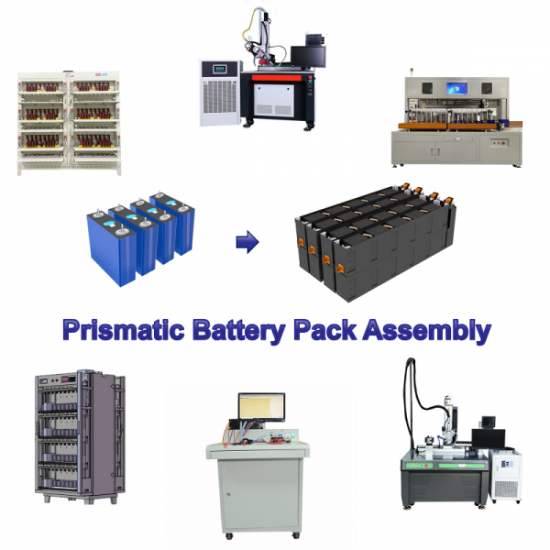

Prismatic Cell Assembly Line

9. Sustainability and EndofLife Strategy

Design for ease of disassembly and serviceability

Support secondlife applications (e.g., energy storage)

Plan for recycling and material recovery

Use ecofriendly materials and packaging

Implement energyefficient lighting and HVAC systems

Types of EV Battery Assembly Plants

Depending on ownership and strategy, these plants can be categorized as:

1. OEM Battery Assembly Plants

Operated by automotive manufacturers

Example: Tesla, BMW, Ford, Rivian

Designed to support inhouse EV production

2. Battery Supplier Assembly Plants

Operated by battery companies supplying to multiple OEMs

Example: CATL, LG Energy Solution, BYD

May include packlevel customization for different clients

3. Joint Venture (JV) Assembly Plants

Collaborations between OEMs and battery makers

Example: BMW & Northvolt, Stellantis & Samsung SDI

Shared investment and expertise

4. ThirdParty Contract Battery Assembly Plants

Built for startups or new EV brands lacking inhouse capabilities

Focus on flexibility and multiclient support

Key Considerations When Building an EV Battery Assembly Plant

When planning or expanding your battery assembly plant, consider the following factors:

| Area | Consideration |

|||

| Location | Proximity to OEMs, logistics, skilled labor |

| Production Capacity | Number of battery packs per year |

| Pack Design Flexibility | Support for multiple vehicle models and platforms |

| Automation Level | Manual, semiauto, or fully automated |

| Factory Layout | Workflow optimization, clean room placement |

| Integration with OEM Systems | Compatibility with vehicle assembly lines |

| Quality Control Systems | Realtime testing and traceability |

| Sustainability Strategy | Energy use, recyclability, waste management |

| Workforce Development | Training for engineers, technicians, and operators |

| Partnerships | Collaboration with battery suppliers, OEMs, and tech providers |

Benefits of an EV Battery Assembly Plant

Accelerates EV production by ensuring a stable supply of battery packs

Reduces timetomarket for new EV models

Improves quality and consistency through controlled assembly

Supports localization of EV supply chains and job creation

Enables cost savings through automation and process optimization

Promotes sustainability through modular design and recycling

Leading Companies in EV Battery Assembly Plant Development

Here are some of the key players involved in designing and operating EV battery assembly plants:

Automotive OEMs:

Tesla (USA) – Multiple Gigafactories with inhouse pack assembly

BMW (Germany) – Gigafactory in Germany with Northvolt

Ford (USA) & SK On (South Korea) – BlueOval battery plants

Rivian (USA) – Inhouse battery pack assembly

Volkswagen Group (Germany) – Investing in European Gigafactories

Stellantis (Global) – Partnering with Samsung SDI and Factorial

Battery Suppliers:

CATL (China) – Supplies battery packs to global OEMs

LG Energy Solution (South Korea) – Building assembly plants globally

BYD (China) – Produces battery packs for its own EVs and others

Samsung SDI (South Korea) – Expanding in North America and Europe

Northvolt (Sweden) – Sustainable battery pack assembly in Europe

Equipment and Automation Providers:

KUKA (Germany) – Robotics and automation solutions

Siemens (Germany) – Digitalization and MES platforms

Trumpf, Coherent, IPG Photonics – Laser welding and cutting systems

B&R Automation (ABB subsidiary) – Smart manufacturing systems

Hanson Robotics, Gree EnergyTech – Integrated battery line solutions

Engineering and EPC Firms:

Bechtel, AECOM, Hatch, Black & Veatch – Turnkey plant construction

Wood, Jacobs, GHD – Engineering and sustainability consulting

Need Help Designing or Optimizing Your EV Battery Assembly Plant?

If you're looking to build, expand, or optimize your EV battery assembly plant, I can help you with:

Master planning – Site selection, capacity roadmap, and zoning

Process engineering – Pack design, integration strategy, automation level

Factory layout design – Workflow optimization, clean room placement

Equipment sourcing – Bestinclass machinery and automation partners

Sustainability strategy – Green energy, recyclability, circular economy

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, environmental permits, worker safety

All you need to do is provide the following information:

Battery pack design and vehicle compatibility

Target annual production capacity (e.g., 50,000 packs/year)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service