Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is an EV Car Battery Lab Plant?

An EV (Electric Vehicle) Car Battery Lab Plant is a dedicated research and development facility focused on the design, testing, and validation of battery cells, modules, packs, and associated technologies for electric vehicles.

Unlike fullscale battery assembly plants or pilot plants, a lab plant operates at a much smaller scale, often with benchtop or semiautomated equipment, and is primarily used for:

Battery chemistry research

Material formulation and electrode development

Cell design and performance evaluation

Thermal, electrical, and safety testing

Battery Management System (BMS) prototyping

Failure analysis and root cause investigation

These facilities are essential for universities, R&D institutions, startups, and automotive companies that want to explore new battery technologies before moving into prototype or pilot production stages.

Key Objectives of an EV Battery Lab Plant

1. Support Fundamental Research and Innovation

Explore novel chemistries like solidstate, sodiumion, silicon anodes, lithiumsulfur

Test alternative materials for cathodes, anodes, electrolytes, and separators

2. Enable Rapid Prototyping and Iteration

Build and test small batches of battery cells under controlled conditions

Quickly modify designs and evaluate performance impacts

3. Conduct InDepth Performance and Safety Testing

Measure energy density, power output, cycle life, and degradation behavior

Perform stress tests including overcharge, short circuit, thermal runaway

4. Validate Battery Components and Systems

Assess BMS algorithms, sensor accuracy, and communication protocols

Evaluate cooling system efficiency and packlevel thermal management

5. Provide Training and Skill Development

Handson experience for researchers, engineers, and students

Exposure to realworld battery testing and failure analysis

6. Serve as a PreDevelopment Hub for Larger Projects

Generate data and insights that inform future pilot lines or Gigafactory investments

Support technology transfer from academia to industry

Core Capabilities of an EV Battery Lab Plant

A wellequipped EV battery lab plant typically includes the following specialized areas and tools:

1. Battery Cell Fabrication Lab

This area supports the development and smallscale production of battery cells.

Key capabilities include:

Slurry preparation: Mixing active materials, binders, solvents

Electrode coating: Slotdie coating, doctorblade, spray coating

Drying and calendering: Removing solvents and adjusting electrode density

Slitting and stacking/winding: Cutting electrodes and assembling cell components

Cell assembly: Sealing pouch or coin cells in glovebox environments

Electrolyte filling: Under dry air or inert gas atmosphere

Formation & aging: First charge/discharge cycle and stabilization

2. Battery Testing and Characterization Lab

This lab focuses on performance evaluation and failure analysis.

Testing capabilities include:

Electrochemical testing: Cyclic voltammetry, EIS (electrochemical impedance spectroscopy)

Capacity testing: Charge/discharge cycles under various temperatures

Cycle life testing: Repeated charging/discharging to assess degradation

Rate capability testing: Highpower discharge/charge performance

Calendar aging testing: Longterm storage under different conditions

Safety testing: Overcharge, external short, nail penetration, crush tests

Thermal testing: Thermal conductivity, heat generation, cooling performance

3. Battery Management System (BMS) Development Lab

The BMS lab supports the design, simulation, and validation of intelligent battery control systems.

Key activities include:

Hardware design: PCB layout, component selection, signal conditioning

Firmware development: Charging algorithms, balancing strategies, diagnostics

Communication protocols: CAN, LIN, Ethernet, wireless connectivity

Functional safety validation: ISO 26262 compliance, fault detection

Simulation and modeling: Digital twins for BMS and battery behavior

Integration testing: With vehicle control systems and cloud platforms

4. Thermal Management and Simulation Lab

This area focuses on managing heat within battery systems.

Capabilities include:

Thermal interface material (TIM) testing

Cooling system design: Aircooled vs. liquidcooled systems

Thermal modeling and simulation: Finite Element Analysis (FEA), CFD

Temperature uniformity testing: Hot spot detection and mitigation

Phase change materials (PCM): Alternative thermal regulation methods

Fire suppression and thermal runaway propagation studies

5. Materials Science and Failure Analysis Lab

This lab supports deep understanding of battery materials and failure modes.

Tools and techniques include:

SEM (Scanning Electron Microscopy) – Analyze microstructure

XRD (Xray Diffraction) – Identify crystal structures

FTIR / Raman Spectroscopy – Analyze chemical composition

EDS (Energy Dispersive Spectroscopy) – Elemental mapping

XPS (Xray Photoelectron Spectroscopy) – Surface chemistry analysis

Crosssectioning and polishing – Prepare samples for inspection

Postmortem analysis – Investigate failed cells and degradation mechanisms

6. Clean Room and Dry Room Infrastructure

To support moisturesensitive operations such as:

Gloveboxes – For handling Limetal, solidstate batteries, etc.

Dry rooms – Humidity <1% RH for electrolyte filling and electrode handling

Air filtration systems – Maintain particulatefree environment

Explosionproof enclosures – For flammable solvent processes

Climatecontrolled storage – For sensitive raw materials and components

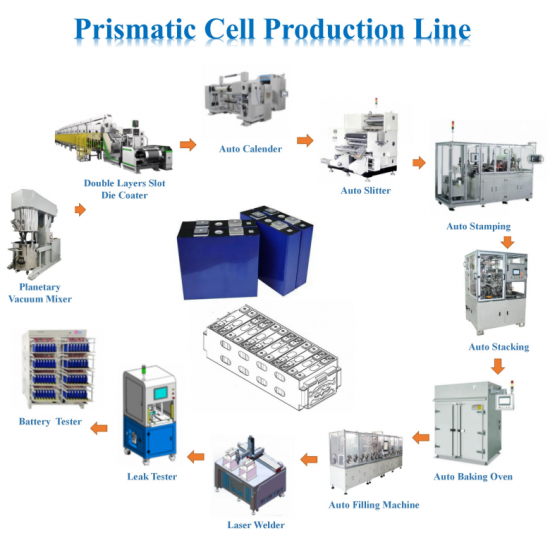

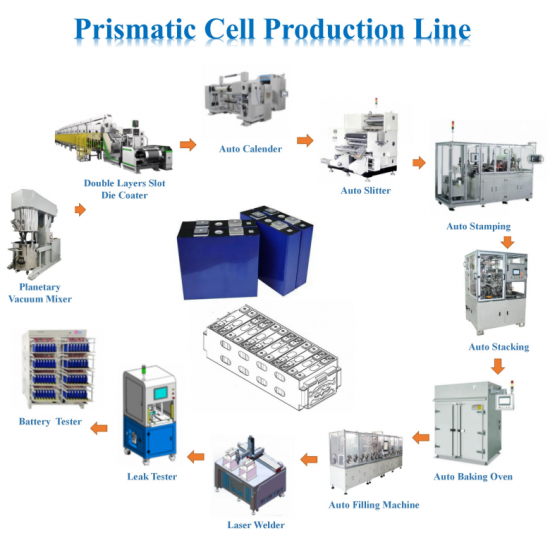

Prismatic Cell Equipments

7. Data Acquisition and Analytics Platform

Modern battery labs use digital tools to track and analyze experimental results.

Features include:

Test automation software – Control charge/discharge cycles

Data logging systems – Record voltage, current, temperature in real time

Cloudbased data storage – Enable collaboration and remote access

Machine learning tools – Predict degradation and optimize battery usage

Digital twins – Simulate battery behavior under different conditions

8. Sustainability and Safety Protocols

Even at a small scale, sustainability and safety are essential:

Battery recycling and material recovery – Recover metals like Li, Co, Ni

Waste treatment systems – Handle hazardous chemicals safely

Fire protection systems – Flameresistant cabinets, suppression agents

Emergency response plans – Fire drills, spill containment, PPE

Worker training programs – Safe handling of reactive materials

Types of EV Battery Lab Plants

Depending on ownership and purpose, these labs can be categorized as:

1. Academic and University Battery Labs

Operated by universities for teaching and fundamental research

Example: MIT Energy Initiative, Stanford Precourt Institute

Focus: Material science, electrochemistry, nextgen battery tech

2. National Research Laboratory Facilities

Governmentfunded centers for advanced battery R&D

Example: Argonne National Lab (USA), Fraunhofer ISE (Germany)

Focus: Technology development, standardization, national innovation

3. Corporate R&D Battery Labs

Owned by automotive OEMs or battery suppliers

Example: BMW Group Battery Lab, Toyota Advanced Battery R&D

Focus: Product development, supplier qualification, IP creation

4. Startup Incubation Battery Labs

Designed for earlystage battery tech companies

Located in innovation hubs or industrial parks

Offer shared infrastructure and mentorship

5. Collaborative IndustryAcademia Labs

Joint ventures between companies and universities

Example: CATL + Tsinghua University, Farasis + Honda

Aim: Accelerate commercialization of academic breakthroughs

Key Considerations When Building an EV Battery Lab Plant

When planning your battery lab, consider the following factors:

| Area | Consideration |

|||

| Location | Proximity to universities, R&D centers, and supply chain |

| Lab Size | Square footage, clean room requirements, ventilation |

| Battery Chemistry | NMC, LFP, solidstate, sodiumion, etc. |

| Facility Type | Benchtop, semiautomated, or modular automation |

| Environmental Compliance | Fire safety, emissions, waste handling |

| Equipment Selection | Cell making machines, testing rigs, analytical tools |

| Data Systems | MES integration, cloud storage, AI analytics |

| Workforce Development | Training for scientists, engineers, and technicians |

| Partnerships | Universities, OEMs, government grants, investors |

Benefits of an EV Battery Lab Plant

Enables cuttingedge research into nextgeneration battery technologies

Accelerates innovation through rapid experimentation and iteration

Reduces risk before investing in largescale manufacturing

Builds technical expertise and intellectual property internally

Supports education and workforce development

Attracts funding and strategic partnerships

Promotes sustainable battery development and circular economy

Leading Institutions and Companies Involved in EV Battery Lab Development

Here are some of the key players involved in designing and operating EV battery lab plants globally:

Academic & Research Institutions:

MIT Energy Initiative (USA) – Battery innovation and policy

Stanford University (USA) – Advanced materials and electrochemistry

Fraunhofer ISE (Germany) – Battery manufacturing and testing

Argonne National Laboratory (USA) – Cell chemistry and materials science

CEALiten (France) – Nextgen battery technologies

NREL (USA) – Sustainable battery development

Automotive OEMs:

BMW Group (Germany) – Internal battery R&D and testing

Toyota (Japan) – Solidstate battery research lab

Ford & SK On (USA/South Korea) – Collaborative battery innovation

Volkswagen Group (Germany) – Battery cell development center

Battery Startups:

Factorial (USA) – Solidstate battery research

QuantumScape (USA) – Lithiummetal battery prototypes

Blue Solutions (France) – Sodiumion and flexible battery R&D

StoreDot (Israel) – Fastcharging battery materials

Equipment and Automation Providers:

Neware, Bitrode, Arbin Instruments – Battery testing systems

Hanson Robotics, Gree EnergyTech – Modular battery line solutions

Koehler Instrument Company – Electrolyte and separator testing

Keysight Technologies – Data acquisition and measurement systems

Engineering and Lab Design Firms:

CRB, Jacobs, GHD, Stantec – Lab planning and construction

Exyte, Linde Engineering, Sweco – Clean room and dry room design

EHS consulting firms – Environmental and safety compliance

Need Help Designing or Optimizing Your EV Battery Lab Plant?

If you're looking to build, expand, or optimize your EV battery lab plant, I can help you with:

Master planning – Site layout, process flow, zoning

Lab design – Clean room placement, ventilation, safety zones

Equipment selection – Cell making tools, testing rigs, analyzers

Sustainability strategy – Waste reduction, green chemistry

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, permits, worker safety

Training and curriculum development – Student and engineer programs

All you need to do is provide the following information:

Battery chemistry and focus area (e.g., solidstate, fast charging, recyclability)

Target annual testing capacity (e.g., 100–1,000 cells/month)

Lab location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service