Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is an EV Car Battery Pilot Plant?

An EV (Electric Vehicle) Car Battery Pilot Plant is a smallscale, advanced manufacturing facility designed to develop, test, and refine battery cell and pack production processes before fullscale commercialization.

Unlike largevolume Gigafactories or battery assembly plants, a pilot plant serves as a technology demonstrator and process development hub, enabling:

R&D on new battery chemistries (e.g., solidstate, sodiumion, silicon anodes)

Validation of novel manufacturing techniques

Process optimization for scalability

Training of engineers and operators

Testing of equipment and automation systems

Compliance with safety, quality, and environmental standards

These facilities are crucial for companies, startups, research institutions, and governments that aim to enter the EV battery industry or develop nextgeneration energy storage technologies.

Key Objectives of an EV Battery Pilot Plant

1. Accelerate Innovation and Technology Development

Enable rapid prototyping and iteration of new battery designs

Support testing of advanced materials and cell architectures

2. Bridge the Gap Between Lab Research and Industrial Production

Translate labscale discoveries into scalable manufacturing processes

Identify and resolve technical and operational challenges early

3. Optimize Manufacturing Processes Before FullScale Investment

Validate equipment performance and integration

Finetune parameters like coating speed, drying efficiency, welding quality

4. Train Engineering and Operations Teams

Provide handson experience with realworld battery manufacturing workflows

Build internal expertise in battery design, assembly, and testing

5. Ensure Compliance with Industry Standards

Test against automotivegrade requirements (e.g., ISO 26262, UN38.3, IEC 62660)

Meet functional safety, thermal management, and durability benchmarks

6. Support Localization of Battery Supply Chains

Help countries or regions develop domestic capabilities in EV battery production

Encourage collaboration between academia, startups, and OEMs

Core Stages in an EV Battery Pilot Plant

A modern EV battery pilot plant typically includes scaleddown versions of the key stages found in fullscale factories, but with greater flexibility and focus on experimentation.

1. Battery Cell Prototyping Line

This line allows researchers and engineers to produce small batches of battery cells for testing.

Key steps include:

Slurry mixing: Testing different formulations of cathode/anode materials

Electrode coating: Evaluating coating thickness, adhesion, and uniformity

Drying & calendering: Optimizing solvent removal and electrode density

Slitting & stacking/winding: Experimenting with cell formats (cylindrical, pouch, prismatic)

Cell assembly: Sealing and welding under controlled environments

Electrolyte filling: Under ultradry conditions (<1% RH)

Formation & aging: First charge/discharge cycle and stabilization

Performance testing: Capacity, resistance, and cycle life

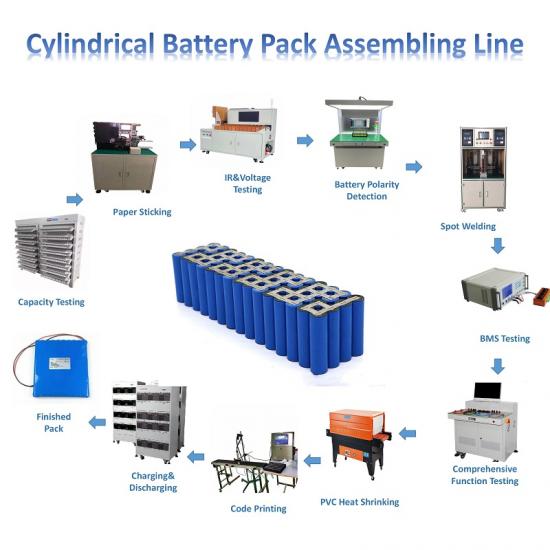

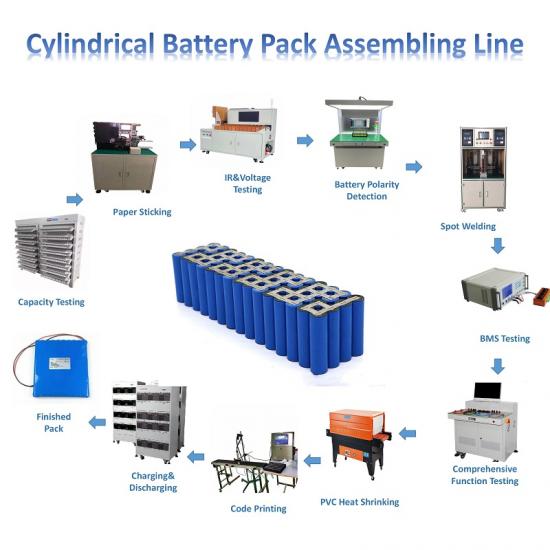

2. Module and Pack Assembly Area

Once cells are validated, they can be integrated into modules and packs.

Steps include:

Cell sorting and grouping: Based on voltage and capacity matching

Module stacking and busbar welding: Exploring different configurations

Thermal interface material application: Testing heat dissipation strategies

BMS integration: Installing sensors and validating communication protocols

Packlevel assembly: Mounting modules into frames with cooling systems

Final pack testing: Functional, electrical, and thermal checks

3. Testing and Validation Lab

A dedicated laboratory ensures that every component and system meets rigorous standards.

Testing includes:

Electrical testing: Voltage, current, internal resistance, efficiency

Mechanical testing: Vibration, drop, compression, crush tests

Environmental testing: Temperature extremes, humidity, salt spray

Safety testing: Overcharge, short circuit, nail penetration, thermal runaway

Cycle life testing: Predicting longterm performance and degradation

Failure analysis: Root cause identification and corrective action

4. Battery Management System (BMS) Development Lab

The BMS is the brain of the battery system. In a pilot plant, this area supports:

Hardware design and PCB layout

Firmware development and overtheair updates

Communication protocol integration (CAN, Ethernet, CAN FD)

Functional safety validation (ISO 26262 compliance)

Fault detection and isolation algorithms

Integration with vehicle control systems

5. Clean Room and Dry Room Infrastructure

To support moisturesensitive operations like electrolyte filling and electrode handling:

Ultralow humidity zones (<1% RH)

Air filtration systems

Solvent recovery and fire suppression systems

Explosionproof enclosures for flammable processes

Climatecontrolled storage areas for raw materials

Cylindrical Battery Pack Assembling Line

6. Digital Manufacturing and Data Analytics Platform

Modern pilot plants use digital tools to track and optimize every step of the process.

Features include:

Manufacturing Execution System (MES) – Realtime data tracking

IoTenabled sensors and PLCs – Monitor process variables

Traceability systems – Track every cell and module from start to finish

Simulation tools – Digital twins for virtual testing

Predictive analytics – Improve yield and reduce defects

7. Flexible Automation and Equipment Integration

Pilot plants often use modular and reconfigurable equipment to allow for:

Rapid switching between cell formats (pouch, cylindrical, prismatic)

Testing of new automation platforms

Integration of robotics for welding, handling, and inspection

Evaluation of laser welding, ultrasonic bonding, and AIbased vision systems

Scalable solutions ready for transfer to fullscale production

8. Sustainability and Safety Systems

Even at a small scale, sustainability and safety are essential:

Energyefficient lighting and HVAC systems

Waste reduction and recycling strategies

Battery reuse and secondlife testing

Fire protection and emergency response plans

Worker training on chemical handling and safety protocols

Types of EV Battery Pilot Plants

Depending on ownership and purpose, these plants can be categorized as:

1. Academic & Research Institute Pilot Plants

Operated by universities or national labs

Focus: Fundamental R&D and technology discovery

Example: Fraunhofer ISE (Germany), Argonne National Lab (USA)

2. Startup Incubation Pilot Plants

Designed for earlystage battery tech companies

Focus: Proofofconcept, investor demonstrations, IP development

Often located in innovation hubs or industrial parks

3. OEM and Tier1 Supplier Pilot Plants

Owned by automotive companies or suppliers

Focus: Preproduction validation and supplier qualification

Example: BMW Group’s battery center, Toyota’s R&D facility

4. GovernmentSupported National Battery Hubs

Backed by national policies and funding programs

Aim: Build local battery capability and attract investment

Example: India’s NITI Aayog battery mission, EU Battery Innovation Hub

5. Collaborative Industry Consortium Pilot Plants

Joint ventures between multiple stakeholders

Share costs, knowledge, and infrastructure

Example: Farasis Energy + Honda, CATL + VW Group

Key Considerations When Building an EV Battery Pilot Plant

When planning your pilot plant, consider the following factors:

| Area | Consideration |

|||

| Location | Proximity to R&D centers, universities, supply chain partners |

| Scale | Annual output (e.g., 1–10 MWh/year for cells, 100–1,000 packs/year) |

| Battery Chemistry | NMC, LFP, solidstate, etc. |

| Cell Format | Cylindrical, pouch, prismatic |

| Automation Level | Manual, semiauto, or modular automation |

| Factory Layout | Clean room placement, workflow, scalability |

| Integration Strategy | Celltopack, modulelevel integration |

| Environmental Compliance | Fire safety, emissions, waste treatment |

| Workforce Development | Training engineers, technicians, and operators |

| Partnerships | Suppliers, OEMs, research institutions |

Benefits of an EV Battery Pilot Plant

Reduces risk in scaling up new technologies

Speeds up timetomarket for innovative battery products

Builds technical expertise and knowhow internally

Enables customization for specific applications or markets

Attracts investment and partnerships through proven capabilities

Supports sustainable development of green battery technologies

Strengthens national or regional battery ecosystems

Leading Companies and Institutions Involved in EV Battery Pilot Plant Development

Here are some of the key players involved in designing and operating EV battery pilot plants globally:

Research Institutions:

Fraunhofer ISE (Germany) – Battery manufacturing and testing

Argonne National Laboratory (USA) – Advanced battery R&D

Oak Ridge National Laboratory (USA) – Materials science and processing

CEALiten (France) – Battery innovation and pilot lines

NREL (USA) – Sustainable battery technologies

Automotive OEMs:

BMW Group (Germany) – Battery cell R&D and pilot production

Toyota (Japan) – Solidstate battery development

Ford & SK On (USA/South Korea) – Pilotscale innovations

Volkswagen Group (Germany) – Internal battery development

Battery Startups:

Factorial (USA) – Solidstate battery pilot line

QuantumScape (USA) – Highenergydensity battery prototypes

Blue Solutions (France) – Sodiumion and lithium metal technologies

StoreDot (Israel) – Fastcharging battery R&D

Equipment and Automation Providers:

KUKA (Germany) – Modular automation and robotics

Siemens (Germany) – MES and digital twin platforms

Trumpf, Coherent, IPG Photonics – Laser welding and cutting

Hanson Robotics, Gree EnergyTech – Integrated battery line solutions

B&R Automation (ABB subsidiary) – Smart manufacturing systems

Engineering and EPC Firms:

Bechtel, Hatch, Black & Veatch – Turnkey plant construction

Wood, Jacobs, GHD – Engineering and sustainability consulting

Need Help Designing or Optimizing Your EV Battery Pilot Plant?

If you're looking to build, expand, or optimize your EV battery pilot plant, I can help you with:

Master planning – Site selection, process flow, zoning

Process engineering – Battery chemistry, format, and production stages

Factory layout design – Clean/dry room integration, workflow

Equipment sourcing – Bestinclass machinery and automation

Sustainability strategy – Green energy, recyclability, circular economy

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, permits, worker safety

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, solidstate, pouch)

Target annual production capacity (e.g., 1–10 MWh/year)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service