Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is an EV Car Battery Fabrication Line?

An EV (Electric Vehicle) Car Battery Fabrication Line refers to the entire manufacturing system used to produce lithiumion battery cells for electric vehicles. This includes all stages from raw material preparation to final cell testing and sorting, forming the core of any modern battery production facility.

Unlike labscale or pilot lines, which focus on research and process validation, a fabrication line is designed for highvolume, repeatable, and automated production of battery cells with consistent quality and performance.

Such a line is essential for:

Battery manufacturers (e.g., CATL, LG Energy Solution, Panasonic, BYD)

Automotive OEMs vertically integrating battery production (e.g., Tesla, BMW, Ford)

New entrants building gigafactories to meet growing EV demand

A full fabrication line ensures that each step — from electrode manufacturing to final formation and aging — is optimized for efficiency, yield, and safety, while meeting stringent automotivegrade quality standards.

Key Objectives of an EV Battery Fabrication Line

1. Mass Production of HighQuality Battery Cells

Ensure consistent electrochemical performance across millions of cells

Meet strict automotive requirements for energy density, cycle life, and safety

2. Scalability and Cost Efficiency

Enable gigawatthour (GWh) scale production

Optimize material usage, labor, and energy consumption

3. Automation and Digital Integration

Implement smart manufacturing systems (MES, SCADA, IoT sensors)

Improve traceability, reduce human error, and enable predictive maintenance

4. Process Control and Quality Assurance

Monitor key parameters (thickness, coating weight, weld strength, etc.)

Detect and correct deviations in realtime

5. Safety and Environmental Compliance

Handle flammable solvents and reactive materials safely

Comply with fire suppression, ventilation, and emissions regulations

Types of EV Battery Fabrication Lines

Depending on the cell format, fabrication lines can be classified into three main types:

1. Cylindrical Cell Fabrication Line

Commonly used by Tesla and others (e.g., 2170, 4680 cells)

Involves winding electrodes into a jellyroll and inserting into a metal can

Known for high thermal stability and ease of packlevel redundancy

2. Pouch Cell Fabrication Line

Uses stacked electrodes enclosed in aluminum laminate pouches

Offers flexibility in shape and size

Widely adopted in passenger EVs and energy storage systems

3. Prismatic Cell Fabrication Line

Features stacked or wound electrodes in rigid rectangular cases

Provides good mechanical stability and packaging efficiency

Used by many OEMs including BMW, Hyundai, and Renault

Each type has its own dedicated equipment and process flow, but they share many common steps.

Core Stages in an EV Battery Fabrication Line

Below are the key stages involved in a typical lithiumion battery cell fabrication line:

1. Electrode Manufacturing

This is the foundation of the entire fabrication line, where both anode and cathode electrodes are produced.

a. Slurry Preparation

Mixing active materials (e.g., NMC, LFP), conductive agents, and binders with solvents

Ensuring uniform dispersion and desired viscosity

Typically done in highshear mixers under controlled conditions

b. Electrode Coating

Applying slurry onto current collectors:

Copper foil for anodes (graphitebased)

Aluminum foil for cathodes (e.g., NMC, LFP)

Slotdie coating is preferred for precision and consistency

Thickness control is critical for performance and safety

c. Drying

Removing solvents in multistage drying ovens

Maintaining low dew point and solvent recovery systems

Ensures no residual moisture remains in the electrode

d. Calendering

Pressing the dried electrode to achieve uniform thickness and density

Affects ion transport and overall energy density

Monitored using laser gauges for tight tolerances

e. Slitting

Cutting coated electrodes into strips of precise width

Minimizing burrs and edge damage to avoid internal shorts

Laser or rotary slitters may be used depending on volume and quality needs

2. Electrode Assembly

Once the electrodes are ready, they are assembled into either a stacked or wound configuration.

a. Stacking (for Pouch and Prismatic Cells)

Alternating positive and negative electrodes with separators

Precision stacking machines ensure alignment and spacing

Often uses vision systems for accuracy

b. Winding (for Cylindrical and Some Prismatic Cells)

Creating a "jellyroll" by winding cathode, separator, and anode together

Tension control and speed synchronization are critical

Automated winding machines ensure repeatability

3. Cell Assembly

After electrode assembly, the components are inserted into the casing and sealed.

a. Casing Insertion

Placing the electrode stack/jellyroll into the cell casing

Testing different casing materials (e.g., steel, aluminum)

b. Tab Welding

Connecting electrode tabs to the terminals using laser welding

Ensuring strong electrical contact and structural integrity

Inspections verify weld depth and strength

c. Electrolyte Filling

Injecting liquid electrolyte in a dry room environment (<1% RH)

Different formulations can be tested for performance and safety

Requires solventfree handling and closedloop filling systems

d. Sealing

Closing the cell hermetically using crimping, laser welding, or ultrasonic sealing

Leak testing ensures longterm reliability and prevents swelling or failure

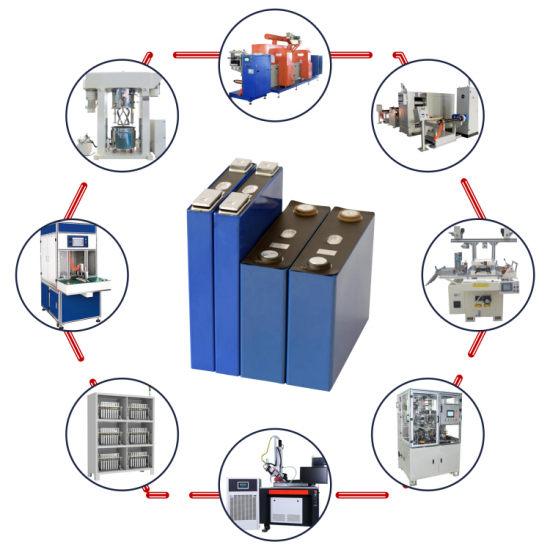

Battery Line Machine

4. Formation and Aging

These steps activate the cell and stabilize its internal chemistry.

a. Formation

First charge/discharge cycle to form the SEI layer on the anode

Done under tightly controlled current and voltage profiles

Realtime monitoring helps identify defective cells early

b. Aging

Allowing the cell to rest under controlled conditions for several days

Helps detect gas generation, internal shorts, or other defects

Thermal chambers simulate accelerated aging for faster results

5. Final Testing and Sorting

Before shipment, each cell undergoes rigorous testing.

a. Electrical Testing

Measuring capacity, internal resistance, and selfdischarge rate

Conducting charge/discharge cycles at various rates and temperatures

b. Safety Testing

Overcharge, short circuit, crush, and nail penetration tests

Thermal runaway detection and protection mechanisms

c. Mechanical Testing

Compression, vibration, and impact testing to ensure durability

d. Sorting and Grading

Grouping cells based on performance metrics

Ensuring balanced packs when integrated into modules and packs

Supporting Systems in an EV Battery Fabrication Line

To ensure safe, efficient, and highquality production, several supporting systems are essential:

1. Clean Room and Dry Room Infrastructure

Maintains ultralow humidity (<1% RH) for sensitive processes like coating and electrolyte filling

Includes air filtration, humidity control, and solvent recovery systems

2. Fire Suppression and Safety Systems

Gas suppression systems (e.g., FM200, Novec 1230) protect against thermal events

Explosionproof enclosures and emergency shutdown systems

3. Manufacturing Execution System (MES)

Tracks every batch, process parameter, and test result

Enables full traceability and supports root cause analysis

4. Data Acquisition and Analytics

Realtime monitoring of temperature, pressure, current, and voltage

Predictive analytics help optimize yield and reduce downtime

5. Waste Management and Sustainability Systems

Solvent recovery units minimize environmental impact

Recycling systems for scrap electrodes and rejected cells

Benefits of an EV Battery Fabrication Line

Enables largescale EV adoption through reliable, highvolume production

Reduces cost per kWh through automation and process optimization

Improves battery performance via tight process control and advanced materials

Enhances supply chain independence for automotive OEMs

Supports innovation by integrating new chemistries and formats (e.g., silicon anodes, dry electrode tech)

Meets global demand with scalable gigafactory models

Design Considerations for an EV Battery Fabrication Line

When planning or expanding your fabrication line, consider the following factors:

Cell Format – cylindrical, pouch, or prismatic?

Battery Chemistry – NMC, LFP, solidstate, etc.?

Annual Capacity Target – 1 GWh, 10 GWh, or 100 GWh?

Level of Automation – semiauto or fully automatic?

Factory Layout and Logistics – space, workflow, and clean room design

Integration with Module/Pack Line – seamless vertical integration

Environmental Compliance – emissions, waste treatment, and sustainability

Local Supply Chain and Labor Availability – impacts cost and scalability

Leading Companies Providing EV Battery Fabrication Line Equipment

Several global companies offer turnkey solutions or key components for battery fabrication lines:

CATL, BYD, LG Energy Solution, Panasonic – Inhouse developed lines and technologies

KUKA, B&R (ABB), Siemens – Automation and digitalization platforms

Hanson Robotics, Gree EnergyTech – Integrated battery production systems

BASF, Umicore, 3M – Material suppliers for cathodes, anodes, and binders

Trumpf, Coherent, IPG Photonics – Laser welding and cutting systems

MTI Corporation, Enerize, Toyo Seiki – Lab and smallscale production tools

Asahi Kasei, Toray Industries – Separator and membrane suppliers

Need Help Designing or Optimizing Your EV Battery Fabrication Line?

If you're looking to build, expand, or optimize your EV battery fabrication line, I can help you with:

Process Flow Design – from raw materials to finished cells

Factory Layout Planning – maximizing space and workflow efficiency

Equipment Selection – recommending bestinclass machinery

Automation Strategy – choosing the right level of automation

Cost Estimation – budget planning based on capacity and complexity

Custom Solutions – adapting the line to your specific chemistry or format

All you need to do is provide the following information:

Battery chemistry and format (NMC, LFP, cylindrical, pouch, prismatic)

Desired annual production capacity (in GWh)

Level of automation required (manual/semiauto/fullauto)

Target application (passenger cars, commercial vehicles, energy storage)

Current factory layout and infrastructure details

Online service

Online service