Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Prismatic Cell Pack Machine?

A Prismatic Cell Pack Machine refers to the automated or semiautomated equipment used to assemble prismatic lithiumion battery cells into modules and then integrate those modules into complete battery packs. These machines are the core components of a battery pack production line, especially for applications in electric vehicles (EVs), energy storage systems (ESS), and industrial equipment like forklifts, AGVs (autonomous guided vehicles), and mining machines.

Unlike cylindrical or pouch cells, prismatic cells are rigid, rectangularshaped batteries usually housed in aluminum or steel casings, which makes them easier to stack and integrate into structured modules and packs.

What Does a Prismatic Cell Pack Machine Do?

A Prismatic Cell Pack Machine performs a range of precision tasks that ensure the safe, efficient, and highquality assembly of battery packs. These include:

1. Cell Handling and Loading

Automatically picks and places prismatic cells from trays or racks into module frames.

Uses robotic arms or gantry systems with vacuum grippers or mechanical clamps.

Ensures accurate orientation and positioning of each cell.

2. Cell Stacking

Arranges cells into predefined configurations (e.g., 1x4, 2x6, etc.).

May involve mechanical alignment and clamping to maintain structural integrity.

Some machines include insulation layer placement between cells for thermal and electrical safety.

3. Busbar Welding

Connects cells electrically using copper or aluminum busbars.

Uses laser welding or ultrasonic welding systems for highquality, lowresistance connections.

Equipped with vision systems to ensure weld accuracy and quality control.

4. Module Housing Installation

Installs protective housing or trays around the stacked cells.

May include automated dispensing of adhesives or thermal interface materials (TIM).

Fastening systems (e.g., screws, clips) are applied using robotic or pneumatic tools.

5. Cooling System Integration

For liquidcooled systems, integrates cooling plates or heat exchangers.

Includes sealing and leak testing of cooling channels.

6. Electrical and Functional Testing

Tests each module for:

Voltage consistency

Internal resistance

Communication with the Battery Management System (BMS)

Some machines include burnin testing or partial charge/discharge cycles.

7. Battery Pack Integration

Assembles multiple modules into a battery pack enclosure.

Integrates the BMS, wiring harnesses, connectors, and safety systems.

May involve packlevel thermal management integration.

8. Final Testing and Quality Assurance

Performs comprehensive functional tests on the complete pack:

Full charge/discharge cycles

Communication checks

Safety interlock verification

Ensures compliance with industry standards such as UN38.3, IEC 62660, and ISO 26262.

9. Labeling and Packaging

Applies serial numbers, barcodes, or QR codes for traceability.

Packages the finished battery pack for safe transport and delivery.

Types of Prismatic Cell Pack Machines

Depending on the level of automation and production goals, these machines come in various forms:

1. Manual Machines

Used for prototyping, smallscale production, or R&D.

Require significant human involvement in loading, assembly, and testing.

Low investment, but lower consistency and throughput.

2. SemiAutomatic Machines

Combine automated functions (e.g., welding, testing) with manual handling.

Offer a balance between flexibility and efficiency.

Ideal for midscale production or custom applications.

3. Fully Automatic Machines

Highspeed, robotdriven systems with minimal human intervention.

Include AI vision systems, realtime data tracking, and MES integration.

Used in largescale EV or ESS manufacturing facilities.

High initial cost but excellent repeatability, traceability, and throughput.

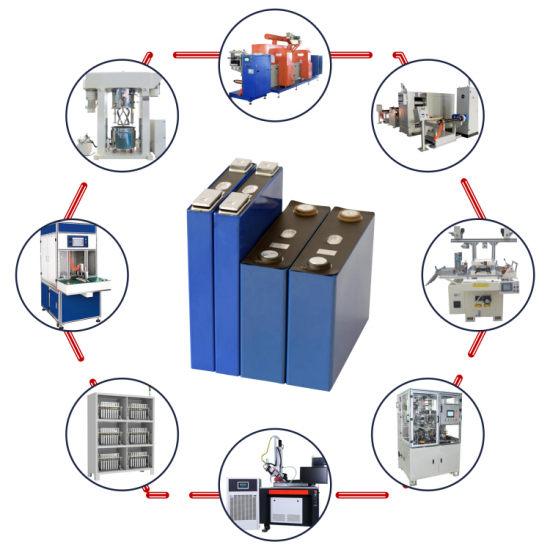

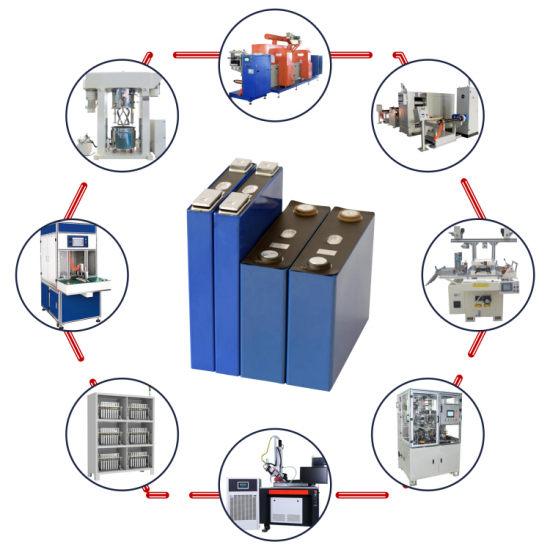

Prismatic Cell Manufacturing Line

Key Components of a Prismatic Cell Pack Machine

To perform the complex tasks involved in pack assembly, these machines integrate various advanced components:

Robotic Arms – For precise cell handling and placement.

Laser Welding Heads – For highquality busbar connections.

Ultrasonic Welding Units – For thin metal connections.

Vision Systems – For alignment verification and weld quality inspection.

Dispensing Systems – For applying thermal paste, glue, or sealants.

Testing Equipment – For electrical, functional, and leak testing.

Conveyor Systems – For seamless movement between workstations.

MES Integration Tools – For digital tracking and process optimization.

Design Considerations When Choosing or Building a Prismatic Cell Pack Machine

When selecting or designing a machine for your production needs, consider the following factors:

Cell Dimensions and Type – Ensure the machine supports your specific prismatic cell format.

Production Volume – Match the machine’s speed and output to your daily or hourly target.

Automation Level – Choose between manual, semiautomatic, or fully automatic based on budget and scalability.

Thermal Management Needs – Decide whether your design requires aircooling or liquidcooling integration.

Integration with BMS – Ensure compatibility with your Battery Management System.

Safety Features – Include fire suppression, emergency stops, and explosionproof enclosures where necessary.

Traceability and Data Logging – Implement systems for full process tracking and quality control.

Applications of Prismatic Cell Pack Machines

These machines are used across a wide range of industries, including:

Electric Vehicles (EVs) – Passenger cars, buses, trucks, delivery vans

Energy Storage Systems (ESS) – Gridscale storage, solar/wind buffering, peak shaving

Industrial Equipment – Electric forklifts, AGVs, mining machines

Transportation – Electric trains, ships, boats, and marine vessels

Benefits of Using a Prismatic Cell Pack Machine

Enables highvolume, repeatable battery production

Ensures consistent quality and safety

Reduces failure risks and improves product reliability

Supports automation and digital monitoring

Lowers labor costs and improves production efficiency

Facilitates customization for different applications and cell types

Leading Companies That Provide Prismatic Cell Pack Machines

Several global companies specialize in supplying or developing prismatic cell pack machines:

KUKA Systems – Advanced robotic automation for battery assembly

B&R Industrial Automation (ABB) – Integrated automation platforms

Gree EnergyTech – Complete module and pack line solutions

Hanson Robotics – Smart battery manufacturing systems

Hyundai WIA – Specialized automotive battery equipment

EnerSys – Experts in energy storage system integration

Tesla (inhouse developed systems) – Custombuilt lines for Gigafactories

Need Help Choosing or Designing a Prismatic Cell Pack Machine?

If you're involved in battery manufacturing, R&D, or equipment procurement, I can help you with:

Understanding the best machine for your cell type and application

Selecting the right level of automation (manual/semiauto/fullauto)

Setting up a production line for different output volumes

Troubleshooting integration or quality issues

Cost estimation and supplier recommendations

Just share the following details:

Prismatic cell dimensions and chemistry

Desired production volume per day

Target application (EV, ESS, industrial, etc.)

Current level of automation in your factory

Online service

Online service