Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Car battery manufacturing plant

What is a Car Battery Manufacturing Plant?

A Car Battery Manufacturing Plant is a largescale industrial facility dedicated to the design, production, testing, and integration of battery systems used in electric vehicles (EVs), hybrid electric vehicles (HEVs), and traditional internal combustion engine (ICE) vehicles. While traditionally focused on leadacid batteries for starter motors and auxiliary power, modern plants now primarily produce lithiumion (Liion) batteries for EVs due to the global shift toward electrified transportation.

These plants can vary in size and scope—from small R&Dfocused pilot lines to fully automated gigafactories producing hundreds of gigawatthours (GWh) of battery capacity annually.

The core operations include:

Battery cell fabrication

Module assembly

Pack integration

Testing and quality assurance

Logistics and supply chain management

Key Objectives of a Car Battery Manufacturing Plant

1. Mass Production of HighQuality Battery Systems

Deliver reliable cells, modules, and packs at scale

Ensure consistency across millions of units

2. Support Electrification Trends

Meet growing demand for EVs globally

Enable automakers to meet emissions targets

3. Reduce Cost per kWh

Optimize material use and process efficiency

Improve automation and yield rates

4. Enable Customization

Support various vehicle platforms with tailored pack designs

Integrate thermal management, BMS, and structural elements

5. Promote Sustainability

Use renewable energy sources

Implement closedloop recycling and waste reduction strategies

6. Ensure Safety and Compliance

Maintain high standards in chemical handling, fire safety, and worker protection

Comply with international regulations and certifications

7. Facilitate Innovation and Technology Transfer

Test new chemistries like LFP, NMC, solidstate, and sodiumion

Scale up promising lab technologies into commercial production

Core Areas Within a Car Battery Manufacturing Plant

1. Cell Production Area

This is where individual battery cells are manufactured through a series of precise steps:

Slurry mixing

Electrode coating and drying

Calendering and slitting

Stacking or winding

Electrolyte filling and sealing

Formation and aging

This area requires strict environmental controls, especially dry rooms with humidity below 1% relative humidity (RH).

2. Module Assembly Area

Once cells are tested and graded, they are grouped into modules:

Spot welding or laser welding of interconnects

Integration of cooling plates, sensors, brackets

Electrical and mechanical integrity checks

Modules serve as building blocks for larger battery packs.

3. Pack Integration Area

Modules are combined into full battery packs:

Installation of the Battery Management System (BMS)

Integration of thermal management systems

Addition of mechanical housing, connectors, and crash structures

Final wiring and insulation

This stage often involves collaboration with OEMs for platformspecific design.

4. Testing and Quality Assurance Lab

Every battery must undergo rigorous testing:

Electrical performance: capacity, resistance, voltage

Mechanical robustness: vibration, impact, sealing

Environmental endurance: temperature extremes, water immersion

Safety tests: overcharge, short circuit, thermal runaway

Only units that pass all criteria are approved for shipment.

5. Storage and Logistics Zones

Raw materials storage (anode/cathode powders, foils, electrolytes)

Component inventory (tabs, separators, cases)

Workinprogress (WIP) staging areas

Finished goods warehouse before delivery to OEMs or customers

Efficient logistics ensure minimal downtime and optimal flow.

6. Support Infrastructure

To maintain safe and efficient operation, several critical support systems are integrated:

Dry room HVAC systems

Fire suppression and gas detection

Solvent recovery and waste treatment

Renewable energy sources (solar, wind, etc.)

Digital manufacturing execution systems (MES)

Types of Car Battery Manufacturing Plants

Plants differ based on ownership structure, production focus, and scale.

1. OEMOwned Plants

Operated by automotive companies

Example: Tesla Gigafactory, Volkswagen PowerCo, BMW Leipzig

Focused on vertical integration and proprietary battery tech

2. Battery Supplier Plants

Run by specialized battery companies

Example: CATL, BYD, Panasonic, LG Energy Solution

Supply multiple automakers globally

3. Joint Venture Plants

Coowned by OEMs and battery suppliers

Example: ACC (France), SVOLT (China), UmicoreSamsung JV

Combine technical expertise and market access

4. Startup and Innovation Plants

Smallerscale, focused on new chemistries or formats

Often backed by venture capital or government grants

Aim to disrupt the market with novel technology

5. National or Regional Battery Hubs

Governmentsupported clusters of battery factories

Example: EU Battery Alliance, India’s PLI scheme, U.S. DOE programs

Aim to build local supply chains and reduce import dependency

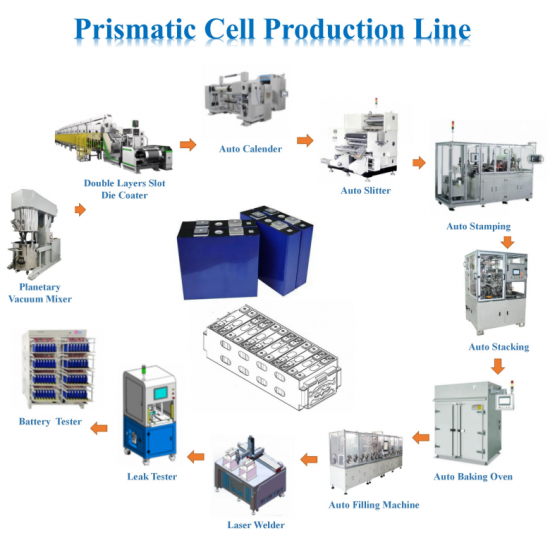

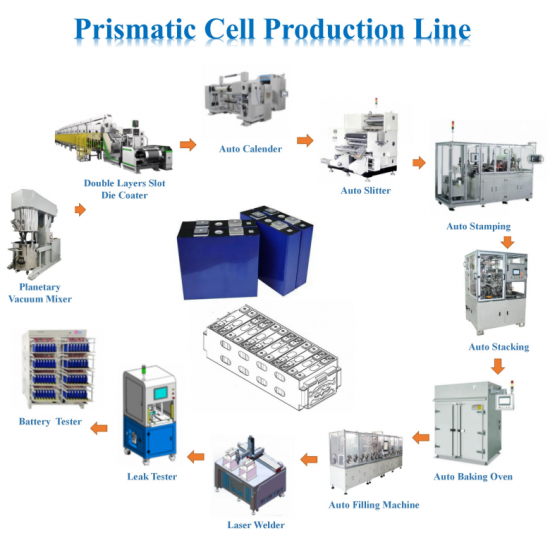

Prismatic Cell Equipments

Supporting Technologies and Systems

To ensure safe, efficient, and sustainable operation, several key technologies are essential:

1. Clean and Dry Room Environments

Dehumidification systems to maintain ultralow humidity

HEPA filters and positive pressure zones

Prevent moisture contamination during sensitive steps

2. Fire Safety and Explosion Protection

Gas detection systems for solvents and hydrogen

Inert gas blanketing in mixing and drying areas

Preaction sprinklers or clean agent suppression systems

3. Automation and Robotics

Robotic arms for electrode handling and stacking

Conveyor systems for WIP transport

Laser welding for highprecision connections

Smart sorting and testing systems

4. Digital Manufacturing Execution (MES)

Realtime monitoring of processes and equipment

IoTbased sensors for environmental conditions

AIdriven vision systems for defect detection

Celllevel traceability from raw materials to delivery

5. Sustainability and Waste Reduction

Solvent recovery systems (e.g., NMP reclamation)

Water treatment and reuse systems

Solar/windpowered facilities

Closedloop battery recycling integration

Applications of a Car Battery Manufacturing Plant

These plants play a crucial role in various industries and markets:

1. Automotive Manufacturers

Provide battery packs for EVs and PHEVs

Reduce reliance on thirdparty suppliers

2. Battery Companies

Sell cells and packs to OEMs and other customers

Expand global presence through localized production

3. Government Agencies

Build national battery supply chains

Support climate goals and job creation

4. Startups and Innovators

Scale up new battery technologies

Partner with OEMs or investors for growth

5. Industrial Parks and Economic Zones

Attract investment and create hightech jobs

Support regional development strategies

Benefits of a Car Battery Manufacturing Plant

Drives the transition to electric mobility

Reduces carbon emissions and fossil fuel dependence

Strengthens local economies and supply chains

Enables innovation in energy storage and vehicle design

Improves energy independence and security

Supports circular economy and sustainability goals

Provides longterm competitive advantage in the EV industry

Leading Countries and Companies in Car Battery Manufacturing

Top Producing Countries:

China – Global leader in Liion battery production

United States – Rapid expansion led by Tesla, Ford, startups

Germany – European hub with VW, BMW, and Northvolt

South Korea – Strong presence from LG, Samsung, SK On

Japan – Pioneer in Liion with Panasonic and Sony

India, France, Canada, Sweden, Poland – Emerging markets investing heavily

Major Players:

CATL (China) – World’s largest EV battery supplier

BYD (China) – Blade battery and vertical integration

Tesla (USA) – Gigafactories and proprietary battery design

Panasonic (Japan) – Longtime partner of Tesla

Samsung SDI & SK On (South Korea) – Highenergydensity solutions

ACC (France) – European battery initiative

Northvolt (Sweden) – Green battery production in Europe

Need Help Designing or Optimizing Your Car Battery Manufacturing Plant?

If you're looking to build, expand, or optimize your car battery manufacturing plant, I can help you with:

Master planning – Site selection, zoning, logistics

Process engineering – Chemistry, format, automation level

Factory layout design – Workflow, clean/dry room integration

Equipment sourcing – Bestinclass machinery and automation

Sustainability strategy – Renewable energy, recyclability

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, permits, worker safety

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, solidstate, cylindrical, pouch)

Target annual production capacity (e.g., 1–100 GWh/year)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service