Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

A Battery Vibration Tester is specialized equipment designed to assess the durability and reliability of batteries when subjected to vibrations. This type of testing is crucial for ensuring that batteries used in various applications, including consumer electronics, electric vehicles (EVs), aerospace, and energy storage systems, can withstand the mechanical stresses they may encounter during transportation, handling, or operation without suffering from performance degradation, internal damage, or safety issues.

Key Features

1. Vibration Simulation

The tester simulates different types of vibrations that a battery might experience in real-world conditions. This includes sine wave vibrations, random vibrations, and shock events. These simulations are based on specific profiles that mimic actual operational environments such as road conditions for EVs or turbulence for aerospace applications.

2. Adjustable Parameters

Users can adjust several parameters including frequency range, vibration amplitude, and duration of the test. This flexibility allows for customized testing protocols tailored to the specific needs of the battery being tested.

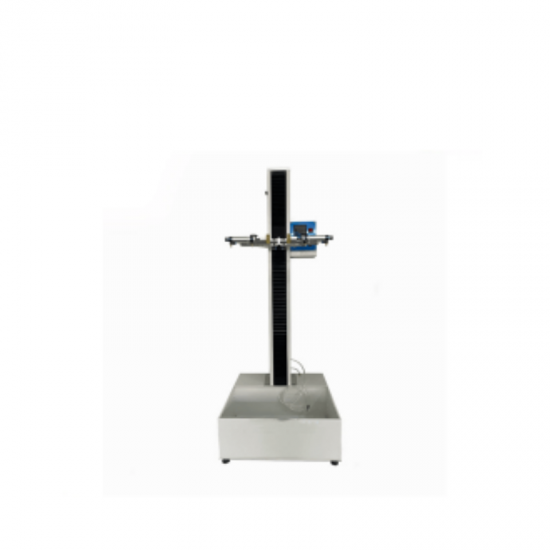

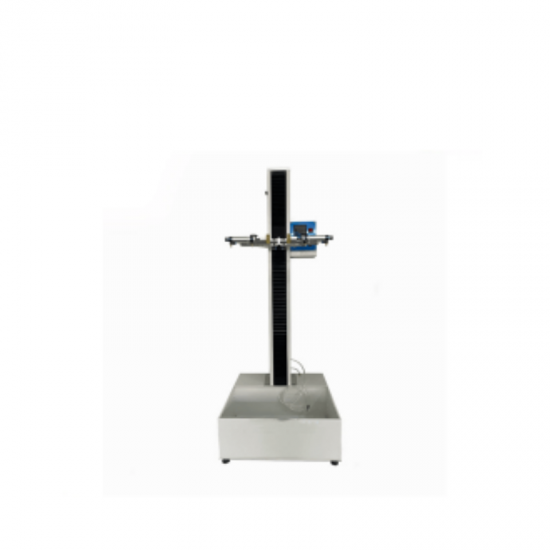

3. Battery Fixtures

Equipped with adjustable fixtures capable of securely holding batteries of various sizes and shapes during the test. Proper securing ensures accurate and repeatable vibration exposure.

4. Data Acquisition System

Advanced testers come with integrated data acquisition systems to monitor and record key parameters such as acceleration, displacement, battery voltage, temperature, and any changes in battery performance before and after the test. This data helps in analyzing the impact of vibration on battery integrity and functionality.

5. Safety Features

Given the potential hazards associated with battery testing under stress conditions, these testers include robust safety features like emergency stop buttons, protective enclosures, and sometimes remote operation capabilities to ensure operator safety.

6. Environmental Controls (Optional)

Some high-end models may include environmental chambers to conduct tests under controlled temperature and humidity conditions, allowing for simulation of extreme environments where the battery might be used or stored.

Battery Electromagnetic Vibration Test Machine

Applications

Consumer Electronics: Ensures that batteries in devices like smartphones, laptops, and wearables can endure the vibrations encountered during daily use and transport.

Electric Vehicles (EVs): Critical for assessing the safety and durability of EV battery packs against the vibrations experienced during driving over rough roads or uneven terrain.

Aerospace: Verifies the robustness of batteries used in satellites, aircraft, and spacecraft against the vibrations encountered during launch and operation in space.

Energy Storage Systems: Tests the stability of large-scale battery systems used in renewable energy installations against mechanical vibrations that could occur during their operational life.

Regulatory Compliance: Helps manufacturers comply with international safety standards and regulations governing battery safety, such as IEC 62619, UN/DOT 38.3, and others.

Considerations When Choosing a Battery Vibration Tester

Test Requirements: Ensure the tester meets your specific test protocols, including frequency range, amplitude, and required data recording capabilities.

Battery Size and Type: Select a tester capable of accommodating the size and shape of batteries you intend to test.

Budget Constraints: Costs vary based on capacity, features, and brand. Determine which features are necessary versus those that are optional.

Ease of Use: Look for user-friendly interfaces and straightforward setup procedures to facilitate efficient testing.

Maintenance and Support: Consider the availability of spare parts, customer support, and maintenance services offered by the manufacturer.

Compliance Standards: Verify that the tester complies with relevant industry standards and certifications required for your application, such as MIL-STD-810 for military applications or ISO standards for automotive and aerospace.

By carefully considering these factors, you can choose a Battery Vibration Tester that not only fits your current testing needs but also supports future growth and compliance requirements. Ensuring the mechanical robustness of batteries through rigorous vibration testing is essential for enhancing product safety and reliability across numerous industries.

Manufacturers specializing in battery testing solutions often provide Battery Vibration Testers as part of their offerings. Consulting directly with these manufacturers or suppliers can help find a solution tailored to specific testing requirements and ensure it meets all necessary safety and performance standards. Examples of such manufacturers could include companies known for their comprehensive range of material and product testing equipment, such as Instron, MTS Systems, and others.

Online service

Online service