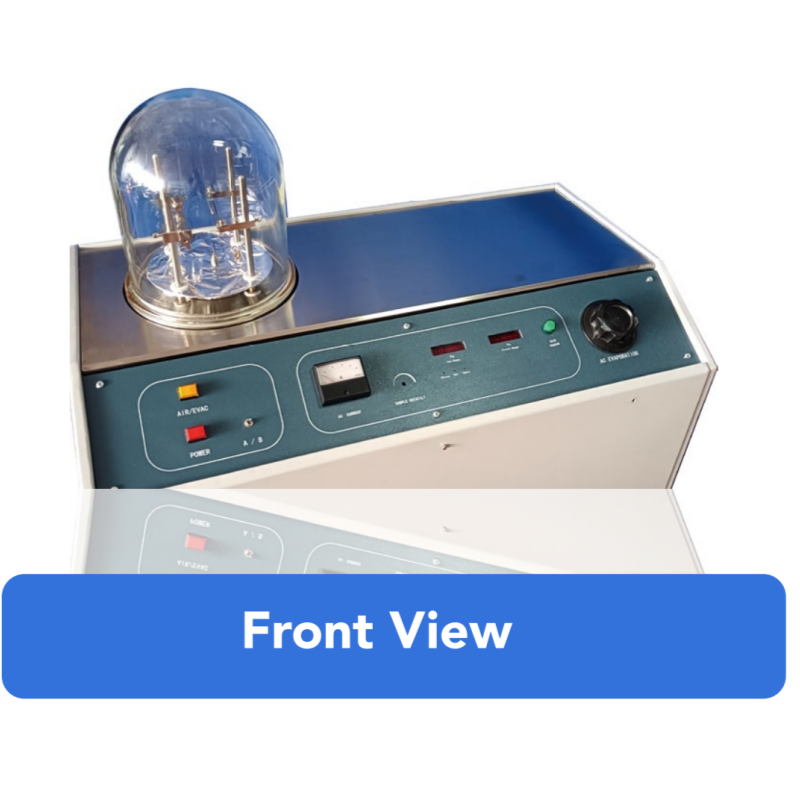

High Vacuum Thermal Evaporation Coater Evaporator System For High-Purity Metal Film Deposition

Model: Lith-BY-ZD06-High Vacuum Thermal Evaporation

Technical Specifications

|

Parameter

|

Specification

|

|

Evaporation Current

|

Max 100 A

|

|

Evaporation Voltage

|

Max 10 V

|

|

Heating Power

|

1,000 W

|

|

Chamber Size

|

Ø230 mm × 280 mm (H)

|

|

Working Vacuum

|

2×10−3 Pa

|

|

Ultimate Vacuum

|

2×10−4 Pa

|

|

Target Materials

|

Carbon, gold & other low-melting metals

|

|

Pumping System

|

Mechanical pump (primary) + Turbo molecular pump (secondary)

|

Key Features

✔ High Vacuum & Fast Deposition

· Advanced compound molecular pump ensures rapid gas evacuation for clean, efficient coating.

· Minimized oil backflow for contamination-free operation.

✔ Reliable & Efficient

· Resistive heating technology for stable evaporation of low-melting metals.

· Simple process with high deposition rates, ideal for lab-scale production.

✔ User-Friendly Design

· Compact chamber accommodates diverse sample sizes (up to Ø230 mm).

· Low maintenance costs for routine use in R&D and academia.

1. Non-Damaging Deposition

· Thermal Evaporation: Gentle heating avoids high-energy plasma, ideal for sensitive samples (e.g., polymers, biomaterials).

· Sputtering Risk: Energetic ions in sputtering may alter delicate surfaces.

2. Faster & Cleaner for Pure Metals

· Higher Deposition Rate: Rapid vaporization of metals (e.g., Au, C) reduces coating time.

· Sputtering Limitation: Slower for low-melting-point materials due to target cooling needs.

3. Minimal Sample Charging

· Uniform Conductive Layers: Smooth metal films (e.g., 5–10 nm Au) prevent SEM charging effectively.

· Sputtering Consideration: Sputtered films may exhibit grainier surfaces, affecting conductivity.

4. Lower Equipment Complexity

· No Gas/Plasma System: Simpler operation and maintenance vs. sputtering’s gas flow/power controls.

· Cost-Effective: Lower power consumption and consumable costs (e.g., replaceable tungsten boats).

Recommended Applications

· SEM Sample Preparation: Conductive coatings for non-conductive or beam-sensitive materials.

· Thin-Film Research: Rapid prototyping of pure metal films (Au, Ag, Al).

· Industrial R&D: Process optimization for specialty coatings.

Ideal For

· Microscopy Labs – Prevents charging in non-conductive samples.

· Material Scientists – Electrode fabrication & conductivity studies.

· Universities – Teaching tool for vacuum deposition principles.

Online service

Online service