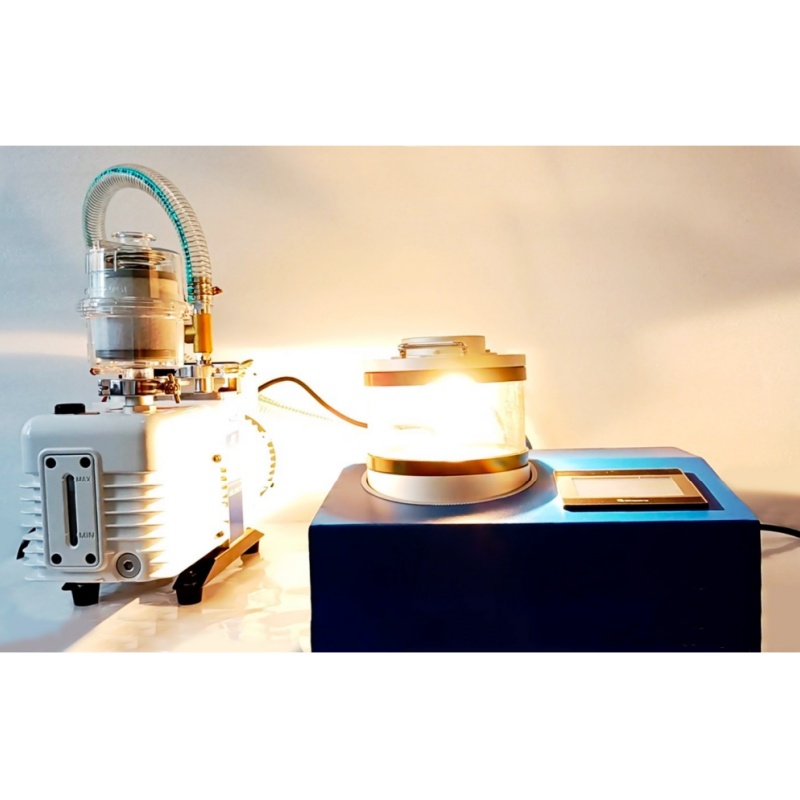

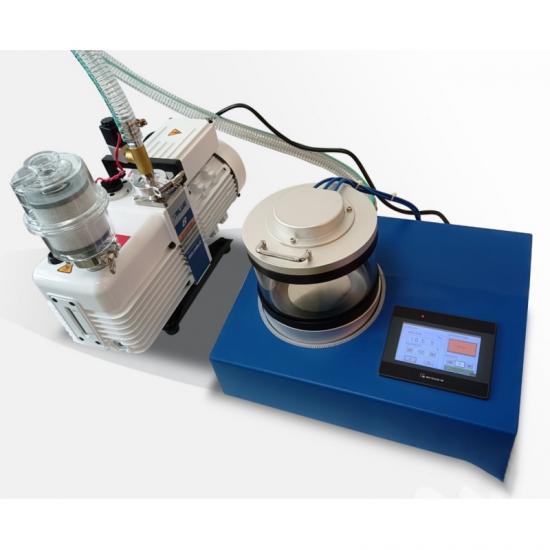

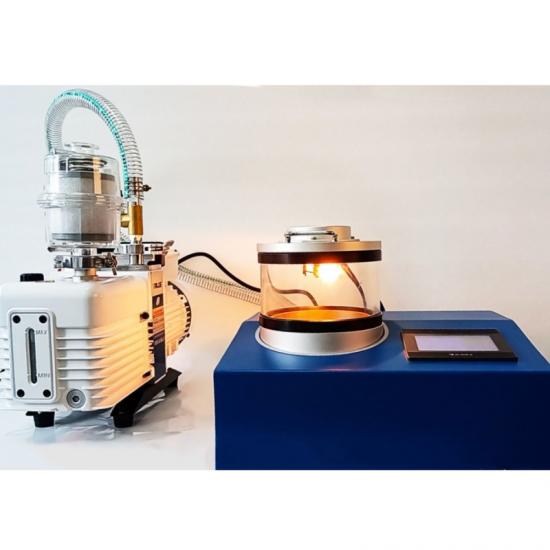

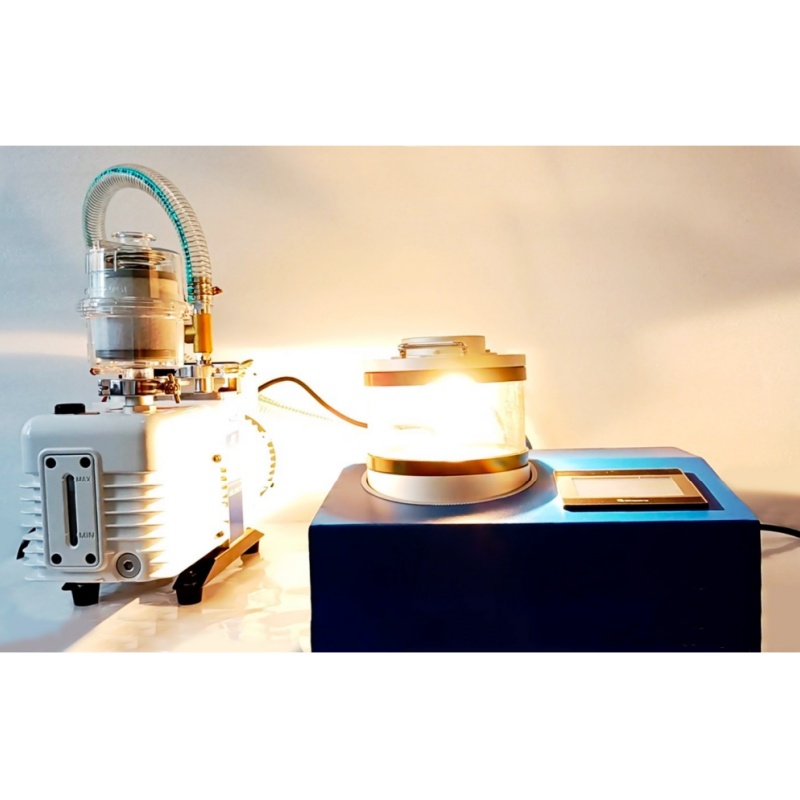

Desktop Pulsing Thermal Evaporation Carbon Metal Deposition Coater PVD System Equipment

Model: Lith-BY-ZD02-Pulsing Thermal Evaporation Carbon Coater

1. Product Overview

Introduction

The Lith-BY-ZD02 Pulsing Thermal Evaporation Carbon Coater is an advanced deposition system designed for ultra-thin carbon film coating in SEM, TEM, and EBSD applications. Utilizing resistive heating of high-purity carbon rope, it enables precise, fast, and contamination-free carbon film deposition with adjustable parameters for optimized coating quality.

Key Technologies & Advantages

✔ Dual Deposition Modes – Supports Flash & Pulsed evaporation (0-9 pulses) for controlled, low-debris coating.

✔ Touchscreen Control – User-friendly interface for precise current/pulse adjustment.

✔ Adjustable Evaporation Current (50A-80A) – Prevents sample damage while ensuring uniform coating.

✔ Vacuum Protection System – Safeguards against low-vacuum short circuits.

✔ Compact & Efficient – Optimized for lab environments with rapid pump-down (<5 min).

2. Technical Specifications

Core Parameters

|

Category

|

Specification

|

|

Model

|

Lith-BY-ZD02

|

|

Dimensions (W×D×H)

|

390mm × 310mm × 290mm

|

|

Chamber Material

|

Borosilicate Glass (Ø160mm × 110mm H)

|

|

Sample Stage

|

50mm (Diameter)

|

|

Evaporation Source

|

High-Purity Carbon Rope

|

|

Deposition Modes

|

Flash / Pulsed (0-9 pulses programmable)

|

|

Max Evaporation Current

|

80A

|

|

Operating Vacuum

|

4–6 Pa

|

|

Ultimate Vacuum

|

5 Pa

|

|

Pump Type

|

2-Stage Rotary Pump (VRD-8, 8 m³/h @50Hz)

|

|

Power Supply

|

220V AC, 50Hz

|

|

Power Consumption

|

1.6 kW

|

|

Weight

|

~50 kg

|

Vacuum System Performance

· Pumping Speed:

o 50Hz: 8 m³/h (2.2 L/s)

o 60Hz: 9.6 m³/h (2.6 L/s)

· Time to Reach Vacuum: <5 minutes (to 2 Pa)

· Vacuum Measurement Range: Atmosphere to 2×10⁻² mbar

3. Applications

· High-Resolution SEM/TEM – Minimizes charging effects.

· EBSD Analysis – Enhances electron backscatter diffraction signals.

· X-ray Microanalysis – Provides conductive layers with minimal interference.

4. Operational Highlights

Pulsed Evaporation Technology

· Reduces Debris: Short pulses limit carbon splashing for cleaner coatings.

· Controlled Thickness: Programmable pulses (0-9) enable repeatable deposition.

User-Centric Design

· Touchscreen Interface: Intuitive control for current/pulse adjustment.

· No Process Gas Required: Simplified operation compared to sputtering systems.

Online service

Online service