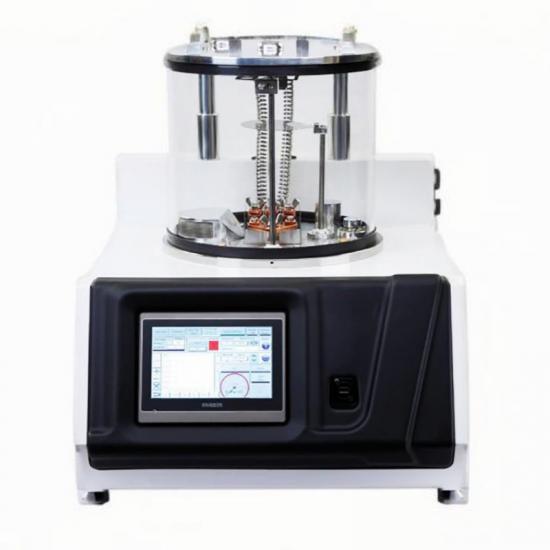

Benchtop Multi-Layer Thermal Evaporator Deposition Coating For Metals, Alloys & Dielectric Film

Lith-ZY-ZD01-Multi-Layer Deposition for Metals, Alloys & Dielectric Thin Films

Product Overview

The Lith-ZY-ZD01 is a desktop thermal evaporation system designed for high-precision thin-film deposition in research and small-scale production. Featuring a turbomolecular pump vacuum system and multi-source evaporation capabilities, it enables efficient deposition of metals, alloys, and dielectric films with minimal operator training.

Key Features & Advantages

1. Wide Application Range

· Materials Research: Metal films, dielectric layers, polymer coatings.

· Functional Devices: Thin-film sensors, optical coatings, nanoelectronics.

· Multi-Layer Deposition: Supports up to 99 layers in a single run.

2. User-Friendly Operation

· Plug-and-play design—no specialized lab environment required.

· 10-inch touchscreen for intuitive control and process monitoring.

· Preloaded 100+ deposition recipes for quick setup.

3. High Precision & Stability

· Quartz crystal monitoring ensures real-time thickness control (≤3% uniformity).

· Turbo-molecular pump (300L/s) achieves ≤6×10⁻⁵ Pa ultimate vacuum.

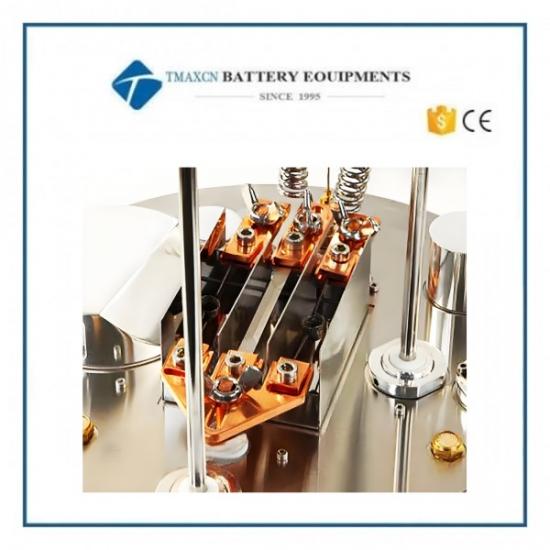

· 3 independent evaporation sources prevent material cross-contamination.

4. Flexible Configuration

· Optional: Co-evaporation for alloys, 400°C substrate heating, and cooled rotating stage.

· Automatic & manual modes for customized process control.

5. Low Maintenance & Compact Design

· Aluminum chamber for efficient heat dissipation.

· 65 kg weight, suitable for benchtop use in labs or offices.

Technical Specifications

|

Parameter

|

Specification

|

|

Chamber

|

Ø300 × 350(h) mm (quartz glass)

|

|

Vacuum System

|

300L/s turbomolecular pump + dual-stage rotary pump

|

|

Ultimate Vacuum

|

≤6 × 10⁻⁵ Pa (after baking)

|

|

Leak Rate

|

≤5.0 × 10⁻⁹ Pa·L/s

|

|

Deposition Rate

|

≥10 nm/min (material-dependent)

|

|

Film Uniformity

|

≤3% (with rotation)

|

|

Evaporation Sources

|

3 independent thermal sources

|

|

Max Layers per Run

|

99 layers (up to 4 materials)

|

|

Control Interface

|

10" touchscreen with programmable recipes

|

|

Power Supply

|

AC 230V, 32A, 50Hz

|

|

Cooling Water (Optional)

|

0.2 MPa, 15–25°C, ≥8 L/min

|

Operational Workflow

1. Automated Deposition: Pre-programmed vacuum pumping, heating, and evaporation.

2. Multi-Layer Control: Supports time-based or thickness-based deposition modes.

3. Remote Monitoring: Adjust parameters via network connection.

Why Choose ?

✔ Combines research-grade performance with desktop convenience.

✔ Minimal training required—ideal for multi-user environments.

✔ Scalable for both experimental and small production needs.

Online service

Online service