Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

A Film Coater is a specialized piece of equipment used primarily in industries like pharmaceuticals, food, and manufacturing for applying a uniform film coating onto solid dosage forms such as tablets, capsules, or even onto films and sheets. In the context of battery manufacturing, a film coater can also refer to machinery designed to apply coatings on electrodes, which is crucial for enhancing the performance and longevity of batteries. However, your query seems to be more general, so I will focus on film coaters used across various industries for product coating.

Key Features

1. Coating Mechanism

Film coaters use different methods to apply coatings, including spray coating, dip coating, roller coating, and curtain coating. The choice depends on the application requirements, such as the type of material being coated and the desired finish.

2. Precision Control

Advanced film coaters offer precise control over parameters like coating thickness, speed, temperature, and humidity. This ensures consistency and quality across batches.

3. Drying System

Postcoating, an efficient drying system (using hot air, infrared heaters, or UV curing) is essential to set the coating properly without defects like cracking or unevenness.

4. Automation Capabilities

Modern film coaters are equipped with automation features that enhance efficiency and reduce human error. These may include automatic feed systems, realtime monitoring, and feedback controls for maintaining optimal operating conditions.

5. Safety Features

Depending on the materials used, film coaters might need safety features such as explosionproof designs, ventilation systems, and emergency stop capabilities to ensure operator safety and compliance with industry standards.

6. Versatility

Highquality film coaters are designed to handle a variety of substrates and coating materials, making them versatile tools suitable for multiple applications across different industries.

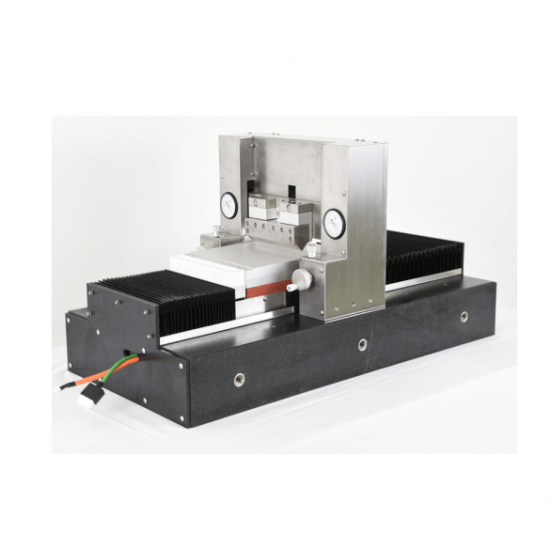

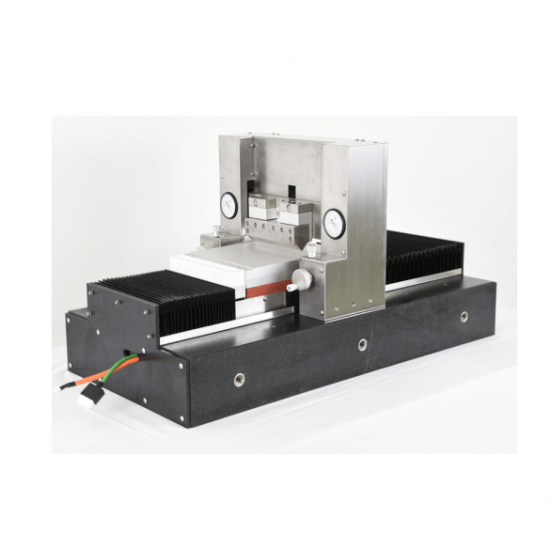

Film Coating Coater

Applications

Pharmaceutical Industry: Used for coating tablets and capsules to improve appearance, stability, swallowability, mask unpleasant tastes, and control drug release.

Food Industry: Applied for coating confectionery items, snacks, or functional foods with flavors, colors, or protective layers.

Manufacturing: Utilized in the production of electronic components, solar panels, and other products requiring a protective or functional coating.

Battery Manufacturing: Specifically, in this context, film coaters are used for applying uniform layers of active materials onto electrodes, which is critical for the performance of lithiumion batteries.

Considerations When Choosing a Film Coater

Application Requirements: Determine what specific needs you have for coating thickness, substrate type, and material compatibility.

Production Scale: Choose a machine that fits your production volume, whether it's for smallscale research or largescale industrial production.

Budget Constraints: Balance between initial cost and longterm operational costs, considering both direct expenses and potential savings from improved efficiency.

Ease of Use and Maintenance: Look for userfriendly interfaces and maintenancefriendly designs to minimize downtime and training.

Compliance Standards: Ensure the machine meets relevant industry standards and regulations, especially important in regulated fields like pharmaceuticals and food production.

By taking these factors into account, you can select a Film Coater that not only addresses your current needs but also supports future growth and compliance requirements. Ensuring highquality, consistent coatings is fundamental to many manufacturing processes, making the selection of appropriate coating equipment a key decision for manufacturers across various sectors. Manufacturers specializing in coating technology often provide a range of film coaters tailored to different applications and scales of production. Consulting directly with these manufacturers can help identify the most suitable model for specific needs. Examples of such manufacturers might include companies known for their expertise in coating solutions, such as Nordson, Bosch Packaging Technology, and others.

Online service

Online service