Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

What is a Car Battery Manufacturing Line?

A Car Battery Manufacturing Line refers to the integrated system of equipment, processes, and workflows used to produce automotive batteries at scale, particularly for modern electric vehicles (EVs). While the term “car battery” can also refer to traditional leadacid batteries used in internal combustion engine (ICE) vehicles, this explanation focuses on the lithiumion battery manufacturing lines that power today’s EVs — including Battery Electric Vehicles (BEVs), Plugin Hybrid Electric Vehicles (PHEVs), and Hybrid Electric Vehicles (HEVs).

This type of manufacturing line is designed for highvolume, consistent, and automated production of battery cells, modules, and packs. It plays a critical role in enabling automakers to meet growing demand for electrified transportation while maintaining high standards of quality, safety, efficiency, and sustainability.

Key Objectives of a Car Battery Manufacturing Line

1. Enable Mass Production of HighQuality Battery Cells

Ensure consistent performance across millions of units

Meet automotivegrade standards such as ISO 26262 and IEC 62660

2. Support Multiple Battery Chemistries and Formats

Allow production of various chemistries:

NMC (Nickel Manganese Cobalt)

LFP (Lithium Iron Phosphate)

SolidState (emerging)

Support different cell formats:

Cylindrical

Pouch

Prismatic

3. Optimize Cost and Efficiency

Reduce material waste and energy consumption

Increase throughput with minimal manual labor

4. Ensure Functional Safety and Reliability

Prevent defects, short circuits, overheating, and thermal runaway

Implement robust testing and quality control systems

5. Integrate Digitalization and Automation

Use smart sensors, AI, and IoT for realtime monitoring

Enable full traceability from raw materials to final product

6. Promote Sustainable and Environmentally Friendly Practices

Minimize emissions and solvent use

Incorporate recycling and circular economy principles

Stages of a Car Battery Manufacturing Line

A full lithiumion car battery manufacturing line typically includes three main stages:

1. Battery Cell Manufacturing (Cell Fabrication)

This stage involves producing individual battery cells, which are the building blocks of modules and packs. This is the most complex and capitalintensive part of the process.

# Substages:

Slurry Mixing:

Active materials (e.g., NMC cathode, graphite anode), binders, and solvents are mixed into a paste.

Electrode Coating:

The slurry is coated onto aluminum (cathode) or copper (anode) foils.

Drying & Calendering:

Solvent is removed in drying ovens; electrodes are compressed to control density.

Slitting:

Electrodes are cut into precise widths for cell assembly.

Stacking/Winding:

Cathode, separator, and anode layers are assembled into a jelly roll (for cylindrical) or stack (for pouch/prismatic).

Encapsulation:

Electrode stack is inserted into a metal can or aluminum pouch casing.

Electrolyte Filling & Sealing:

Cells are filled with electrolyte under ultradry conditions (<1% RH) and sealed.

Formation & Aging:

Initial charge/discharge cycle to activate the cell; by resting period for stabilization.

Testing & Sorting:

Cells are tested for voltage, capacity, and internal resistance; then sorted into performance groups.

2. Module Assembly Line

Once cells are produced, they are grouped into modules, which serve as intermediate units before being integrated into battery packs.

# Substages:

Cell Inspection:

Final visual and electrical inspection before module assembly.

Busbar Installation:

Electrical connections between cells using conductive busbars.

Thermal Interface Material (TIM) Application:

Heatconductive pads or glue applied between cells and cooling plates.

Module Housing Assembly:

Cells are placed into a structural housing with integrated sensors and brackets.

Wiring & BMS Integration:

Internal wiring and integration of the Module Management Unit (MMU) or part of the BMS.

Functional Testing:

Voltage balance, communication signals, and thermal performance checks.

Labeling & Traceability:

Each module is labeled with serial number and key parameters.

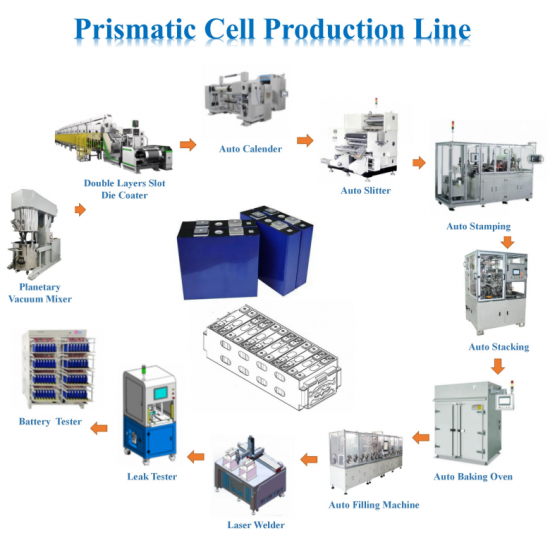

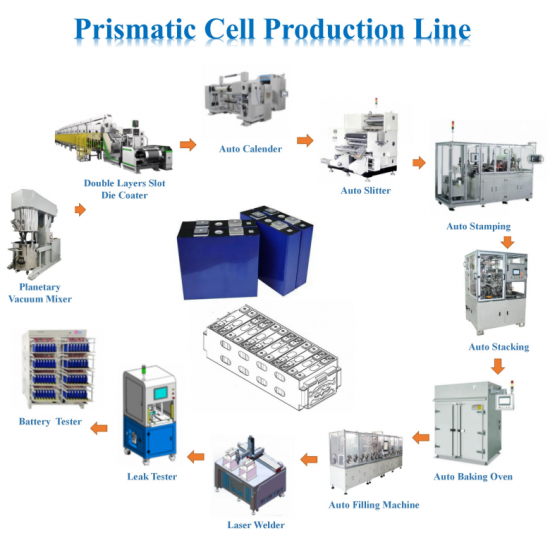

Prismatic Cell Equipments

3. Pack Assembly Line

The final stage involves integrating multiple modules into a complete battery pack, ready for installation in the vehicle.

# Substages:

Module Placement:

Modules are loaded into the pack housing (aluminum or steel frame).

PackLevel Cooling System Integration:

Liquid cooling plates or air channels are installed for thermal management.

BMS Installation:

The central Battery Management System is mounted and connected.

HighVoltage Harness Installation:

Main power cables and connectors are attached.

Structural Bonding & Sealing:

Pack is sealed to meet IP67 or higher protection rating.

Final Functional Testing:

Full pack test including insulation, highvoltage integrity, and communication with vehicle ECU.

Leak Testing & Safety Validation:

Ensures no moisture ingress and safe operation under pressure changes.

Pack Labeling & Shipping Preparation:

Final quality check, labeling, and packaging for delivery to vehicle plant.

Supporting Infrastructure in a Car Battery Manufacturing Line

To ensure smooth and safe operations, several critical support systems must be integrated:

1. Clean Room & Dry Room Systems

Ultralow humidity zones (<1% RH) for electrolyte filling and electrode handling

HEPA filtration to remove particulates

Climatecontrolled storage for sensitive materials

2. Fire Safety & Explosion Protection

Gas detection systems for solvent vapors and electrolyte leaks

Inert gas blanketing in solvent mixing and drying zones

Fire suppression systems using clean agents or water mist

Explosionproof enclosures for flammable processes

3. Waste Management & Sustainability

Solvent recovery systems – Reuse of NMP (NMethyl2pyrrolidone)

Battery recycling integration – Closedloop material recovery

Energyefficient HVAC and lighting

Water treatment systems – For cleaning and process water

4. Digital Manufacturing & Process Control

MES (Manufacturing Execution System) – Realtime data tracking

IoT sensors and PLCs – Monitor pressure, temperature, humidity

AIbased vision systems – Detect defects in electrodes and cells

Traceability systems – Track every cell from raw materials to shipment

5. Automation & Robotics

Automated conveyor systems – Move materials and components

Robotic arms – Handle electrodes, stack components, and load/unload machines

Laser welding and cutting – Highprecision joining and trimming

Smart testing systems – Autosort cells based on test results

Types of Car Battery Manufacturing Lines

Depending on ownership, scale, and technology focus, these lines can be categorized as:

1. Gigafactory Production Lines

Largescale, fully automated lines (10–100 GWh/year)

Example: Tesla Gigafactory Nevada, CATL, LG Energy Solution

2. OEMOwned Battery Production Lines

Operated by automotive companies to control battery supply

Example: BMW Group, Toyota, Ford + SK On

3. Battery Startup Production Lines

Focused on niche technologies like solidstate or sodiumion

Example: QuantumScape, Factorial, Blue Solutions

4. Joint Venture or Consortium Lines

Shared ownership between OEMs and suppliers

Example: Stellantis + Samsung SDI, VW + Umicore

Key Considerations When Designing a Car Battery Manufacturing Line

When planning your battery manufacturing line, consider the following factors:

| Area | Consideration |

|||

| Location | Proximity to raw materials, logistics, and skilled workforce |

| Battery Chemistry | NMC, LFP, solidstate, etc. |

| Cell Format | Pouch, cylindrical, or prismatic |

| Annual Capacity | Target output (e.g., 1–10 GWh/year) |

| Automation Level | Manual, semiauto, or fully automated |

| Factory Layout | Workflow, clean room placement, scalability |

| Environmental Compliance | Fire safety, emissions, waste treatment |

| Workforce Development | Training engineers, technicians, and operators |

| Partnerships | Suppliers, OEMs, research institutions |

Benefits of a Car Battery Manufacturing Line

Enables largescale production of EVs with consistent battery supply

Reduces dependency on external suppliers and lowers cost risks

Improves product quality and customization for specific vehicle platforms

Strengthens local or national battery supply chains

Supports job creation and economic development

Accelerates the transition to electric mobility

Encourages sustainable and circular battery ecosystems

Leading Companies Involved in Car Battery Manufacturing Line Development

Here are some of the key players involved in designing and operating car battery manufacturing lines globally:

Battery Manufacturers:

CATL (China) – World’s largest battery producer

LG Energy Solution (South Korea) – EV battery gigafactories

Samsung SDI (South Korea) – Highenergydensity cells

BYD (China) – LFP and blade battery technology

Panasonic (Japan) – Partner of Tesla, cylindrical cell specialist

Automotive OEMs:

Tesla (USA) – Gigafactories for NMC and LFP cells

Volkswagen Group (Germany) – Cellforce Group for solidstate batteries

Ford Motor Company (USA) – Joint venture with SK On

BMW Group (Germany) – Strategic battery partnerships and internal R&D

Toyota (Japan) – Solidstate battery development and plant construction

Equipment and Automation Providers:

KUKA (Germany) – Robotics and automation

Siemens (Germany) – MES and digital twin platforms

Trumpf, Coherent, IPG Photonics – Laser welding and cutting

Hanson Robotics, Gree EnergyTech – Integrated battery line solutions

B&R Automation (ABB subsidiary) – Smart manufacturing systems

Engineering and EPC Firms:

Bechtel, Hatch, Black & Veatch – Turnkey plant construction

Wood, Jacobs, GHD – Engineering and sustainability consulting

Need Help Designing or Optimizing Your Car Battery Manufacturing Line?

If you're looking to build, expand, or optimize your car battery manufacturing line, I can help you with:

Master planning – Site selection, process flow, zoning

Process engineering – Battery chemistry, format, and production stages

Factory layout design – Clean/dry room integration, workflow

Equipment sourcing – Bestinclass machinery and automation

Sustainability strategy – Green energy, recyclability, circular economy

Cost estimation and ROI analysis – CapEx, OpEx, breakeven modeling

Compliance and safety systems – Fire protection, permits, worker safety

All you need to do is provide the following information:

Battery chemistry and cell format (e.g., NMC, LFP, solidstate, pouch)

Target annual production capacity (e.g., 1–10 GWh/year)

Plant location and available infrastructure

Level of automation and digitalization desired

Current team expertise and strategic goals

Online service

Online service