RF Magnetron Sputtering System for Metals & Non-Metals: Insulators, Semiconductors, Carbon-Based Thin Film Deposition

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

Lith-HZ-JS04Payment:

L/C D/A D/P T/T Western UnionShipping port:

Xiamen PortLead Time:

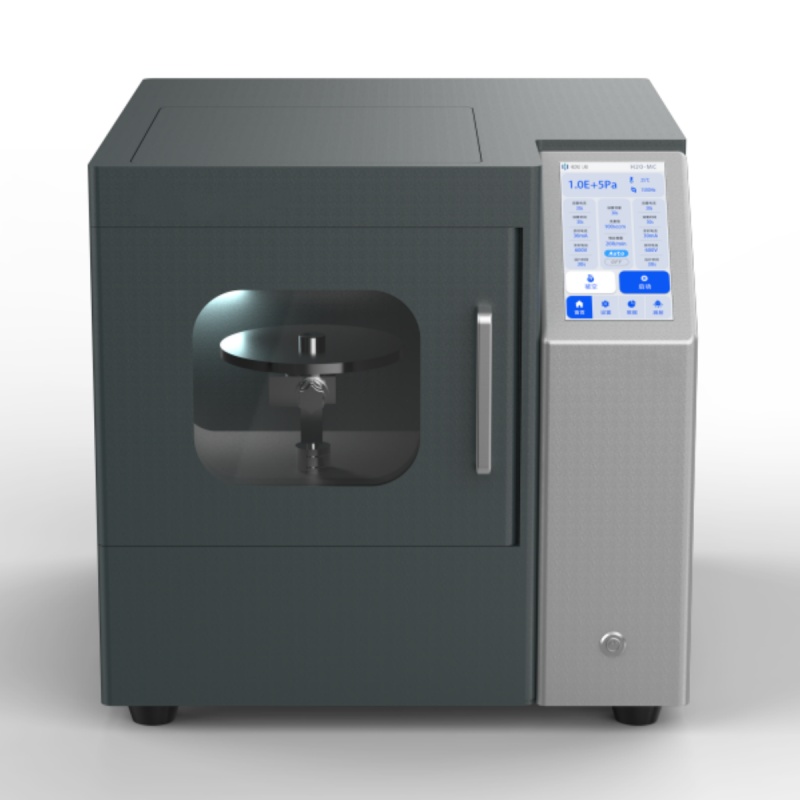

5 daysSmall High-Vacuum Dual-Target Magnetron Ion Sputtering Coating System Coater

Model: Lith-HZ-JS04- High-Vacuum Dual-Target Sputtering Coater

Technical Parameters

|

Category |

Specification |

|

Model |

Lith-HZ-JS04 |

|

Vacuum System |

Oil-free diaphragm pump + molecular pump |

|

Ultimate Vacuum |

≤1.0×10⁻⁴ Pa |

|

Pressure Measurement |

Full-range cold cathode gauge + front-end Pirani gauge |

|

Gas Control |

MFC (Mass Flow Controller) for Ar/O₂/N₂ |

|

Target Configuration |

Dual targets (independent control, alternate/synchronous sputtering) |

|

Target Compatibility |

Metals, alloys, compounds (custom sizes available) |

|

Optional Feature |

Real-time thickness monitoring (nanometer precision) |

|

Cooling System |

Energy-efficient target cooling |

|

Safety Protections |

Overpressure/overcurrent/overheat protection, vacuum interlock, emergency vent |

1. Dual-Target Flexibility

·Enables multi-material deposition (e.g., bilayers, graded films, or interfaces) in a single run.

2. High-Vacuum Precision

·Ultra-low base pressure (≤1.0×10⁻⁴ Pa) minimizes contamination for high-purity films.

3. Intelligent Process Control

·MFC-regulated gas flow ensures repeatable reactive sputtering (e.g., oxides/nitrides).

4. User-Optimized Design

·Energy-saving pumps and cooling reduce operational costs without compromising performance.

· Semiconductors: Electrode/metallization layers, barrier films.

· Optics: Anti-reflective, conductive, or hard coatings.

· Energy: Thin-film batteries, solar cell layers.

· Research: Nanomaterials, heterostructures, surface engineering.

· Lab to Production: Scalable for both R&D prototyping and industrial batch processing.

· Safety & Reliability: Automated safeguards protect equipment and users.

· Customizable: Adaptable to diverse materials and film architectures.

Online service

Online service Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8618559646958

+8618559646958