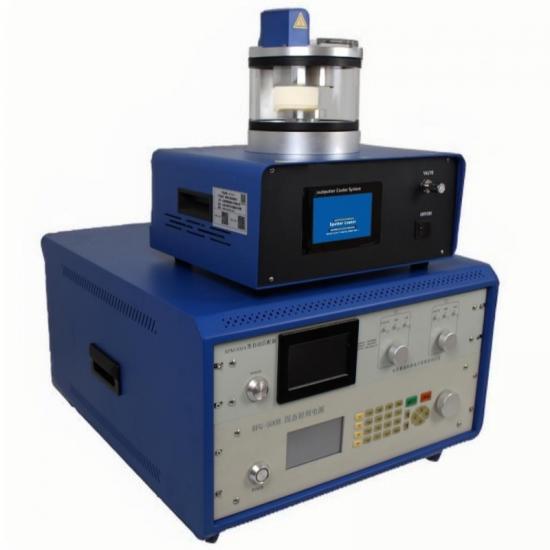

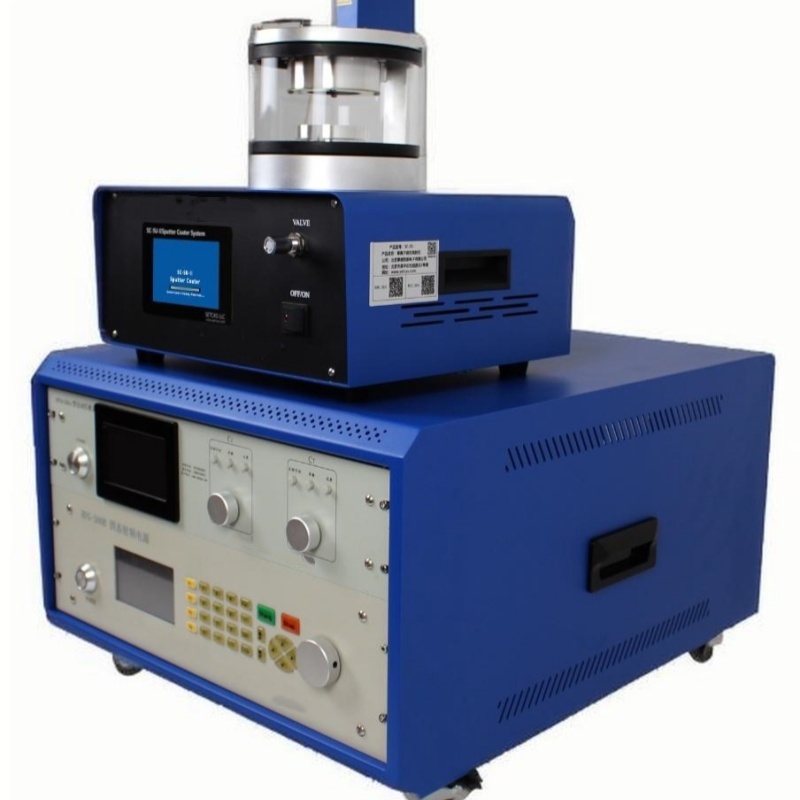

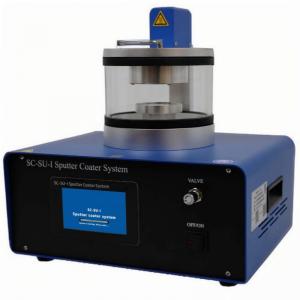

Product Specifications

|

Parameter

|

Specification

|

|

Model

|

Lith-SD-01

|

|

Type

|

RF Magnetron Sputtering System

|

|

Chamber Size

|

150 × 120 mm

|

|

Target Material

|

50 mm diameter (metals & non-metals, thickness: 1–2 mm)

|

|

RF Power

|

Adjustable (1–500 W)

|

|

RF Frequency

|

13.56 MHz

|

|

Matching Network

|

Automatic impedance matcher

|

|

Sputtering Area

|

50 mm

|

|

Ultimate Vacuum

|

5 Pa (base pressure)

|

|

Process Gases

|

Argon, nitrogen, and other inert gases (flow rate adjustable)

|

|

Max. Deposition Rate

|

8 nm/min

|

Key Features & Applications

1. Versatile RF Sputtering for Metals & Non-Metals

· RF Power & Auto-Matching: 13.56 MHz RF with automatic impedance matching ensures stable sputtering of both conductive and insulating materials (e.g., oxides, ceramics).

· Broad Applications: Ideal for advanced thin-film research in semiconductors, optics, and functional coatings.

2. Precise Gas Control & High Vacuum Performance

· Adjustable Inert Gas Flow: Supports Ar, N₂, and other inert gases for controlled deposition environments.

· High Purity Deposition: Base vacuum of 5 Pa minimizes contamination, ensuring high-quality film growth.

3. User-Friendly & Efficient Operation

· Quick Target Change: Compatible with 50 mm targets (1–2 mm thick) for flexible material testing.

· Preset Process Recipes: Saves and recalls parameters for repeatable experiments and production.

4. Stable & High-Speed Deposition

· Max Deposition Rate: 8 nm/min with excellent film uniformity.

· Automated Matching: Reduces manual tuning and enhances process stability.

Recommended Applications

✔ Research & Development: Thin-film studies for semiconductors, dielectrics, and optical coatings.

✔ Small-Scale Production: Prototyping and specialized coating applications.

✔ Multi-Material Sputtering: Supports both metallic and non-metallic targets for diverse material systems.

Online service

Online service