RF Magnetron Sputtering System for Metals & Non-Metals: Insulators, Semiconductors, Carbon-Based Thin Film Deposition

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

Lith-JY-JS02Payment:

L/C D/A D/P T/T Western UnionShipping port:

Xiamen PortLead Time:

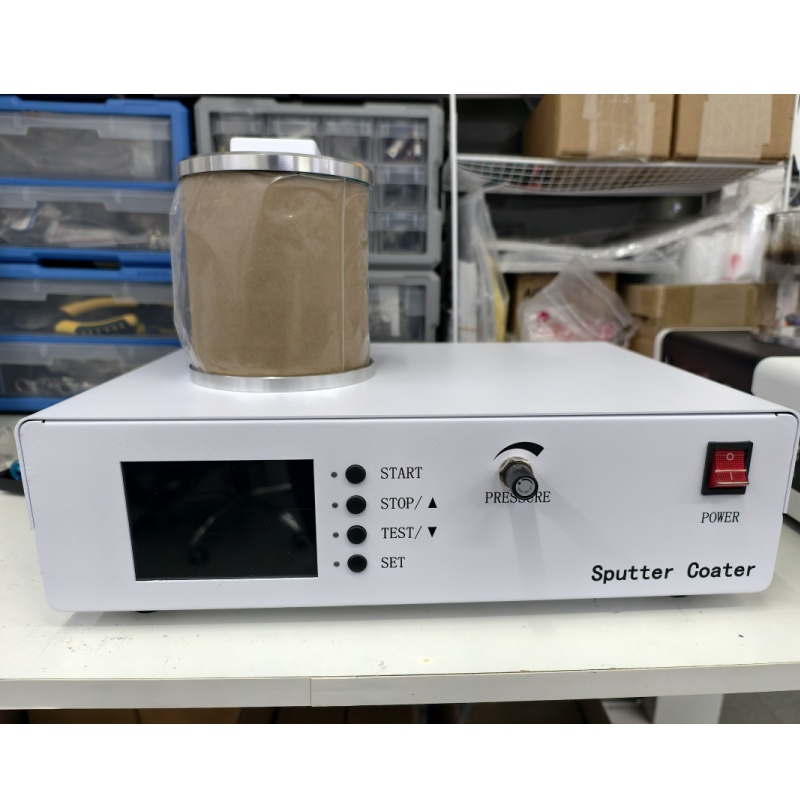

5 daysDesktop Cold Magnetron Sputtering Deposition System For Conductive Coating Of SEM Sample Preparation

Model: Lith-JY-JS02-Cold Magnetron Sputtering Deposition System

The Lith-JY-JS02 is a benchtop cold magnetron sputtering coating system equipped with a standard rotating/tilting sample stage. It is specifically designed for high-quality conductive coating of non-conductive samples with varied surface morphologies for SEM imaging. It also meets the requirements for electrode coating, semiconductor materials, and other thin-film applications.

· "Ultra-Cold" Sputtering: Utilizes a high-efficiency, low-voltage DC magnetron source to prevent thermal damage to sensitive samples.

· Wide-Angle Coverage: Innovative magnetron design ensures uniform coating coverage, even for closely positioned samples.

· Fast Operation: Independent solenoid valves for venting, purging, and exhaust enable rapid system cycling.

· Stable Coating Performance: Precisely controlled sputtering current ensures consistent deposition rates and optimal coating quality, unaffected by chamber pressure.

· Multi-Material Compatibility: Supports various metal targets (Pt standard, optional Au, Au/Pd, or Pt/Pd) with quick and easy target replacement.

|

Parameter |

Specification |

|

Target Material |

Standard: Pt (57mm diameter × 0.1mm thickness) <br> Optional: Au, Au/Pd, Pt/Pd |

|

Sample Stage Rotation |

0–60 rpm (continuously adjustable) |

|

Sample Stage Tilt |

-45° to +45° (continuously adjustable) |

|

Stage Diameter |

40mm (holds 4 standard sample holders; custom sizes available) |

|

Sputtering Current |

Microprocessor-controlled (0–99 mA) with safety interlock |

|

Vacuum Range |

Atm ~3 Pa |

|

Control Method |

Programmable (1–999s) with Start/Pause buttons; automatic pumping/sputtering/venting |

|

Parameter |

Specification |

|

Pumping Speed |

133 L/min |

|

Ultimate Vacuum |

0.05 Pa |

|

Noise Level |

56 dB |

· Ideal for SEM Sample Preparation: Ensures high-conductivity coatings without thermal damage, critical for delicate or heat-sensitive materials.

· Versatile Material Deposition: Suitable for Pt, Au, and alloy coatings in semiconductor, nanotechnology, and materials research.

· User-Friendly Operation: Automated processes and ergonomic design enhance efficiency and reproducibility.

· Compact & Reliable: Benchtop design saves lab space while delivering professional-grade performance.

Online service

Online service Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8618559646958

+8618559646958